Design - Vehicle Movement System

|

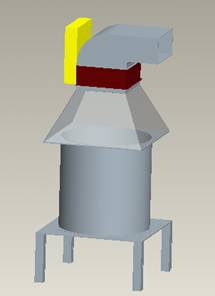

The Vehicle Movement System is designed to produce wind generation that replicates vehicle movement for the training simulators. The team also wants to provide variable wind conditions within the system that mimic the velocity, frequency, and variations of a vehicle’s movement through the desert.

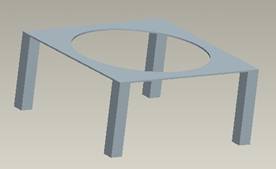

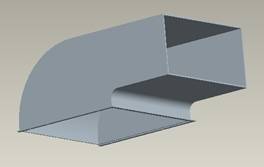

The components of this system must be able to assemble and disassemble fairly easily and in a timely matter. This is because the entire system must break down into smaller pieces to be moved and stored when the trailer is being transported. The system will be designed to break down into five different parts. These include the fan mount, fan assembly, reducing duct section, heat generating device, and exiting vent section.

System Specifications Due to the many different training scenarios that the soldiers are exposed to, this system must be able to handle a variety of wind speeds that can be integrated into a computer controlled system. Based on sponsor recommendations and what the design team had seen during the visit of the simulator, the specifications seen in the table below were chosen for the Vehicle Movement System.

Vehicle Movement System Specifications

System Component Selection

|

|||||||||||||

Home

Page

| Team

Members |

Problem Scope

| Design |

Fabrication

|

Testing

|

Deliverables |

|

|

|||||

|

|

|||||