Overview

Project Description

A prototype of a non-electric, mechanically driven mechanism which accurately measures the date for 100 years.

Key Goals

Mechanical powered movement, minimum maintenance, accurate, aesthetically pleasing, visible.

Stakeholders

- Advanced Manufacturing Training Center at Tallahassee Community College

- Sponsors (Amy O’Donnell, Robert Parsons, David Sellers, Rick Frazier)

- Team Members (Zachary Brower, Michael Patrick, Alyna Segura-Sanchez, Jacob Williams)

- Tallahassee Community

- Horologists

- Power System Engineering Industry

- Power Industry

- Future Senior Design Teams that continue forward with this project

Assumptions

- Mechanism requires little to no maintenance

- Mechanism will not be tampered with

- Mechanism can fit through doorway

Customer Needs

- Mechanism powered using only mechanical processes

- Mechanism accounts for leap years

- Internal workings of mechanism will be visible

- Mechanism uses cost-effective materials without sacraficing quality

- Mechanism displays a traditional American date

- Mechanism is compact and powered alternatively

Functional Decomposition

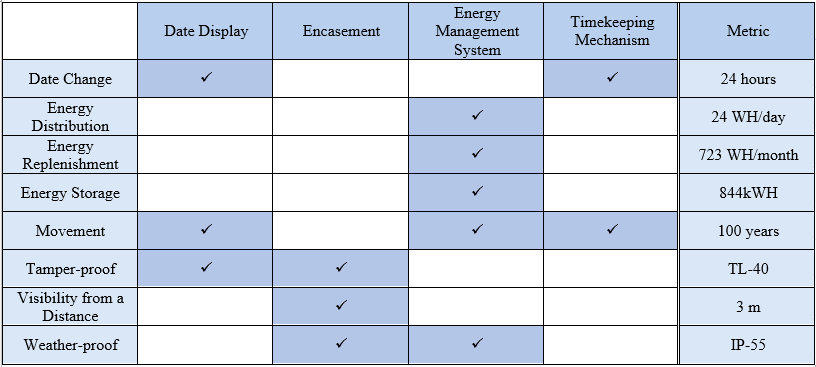

After clarifying the customer’s wants and needs, the specific requirements and specifications of the calendar must be determined. To accomplish this, the flow chart in Table 2 was created based off the interpreted customer needs from Table 1. Using the interpreted needs, the most important aspects of the mechanism were determined. For example, one of the interpreted needs mentions that the calendar must account for leap years. From this need, it is clear that the time-keeping mechanism plays an important role within the entire mechanism, so one branch was created specifically for the time-keeping mechanism. The other branches were determined in a similar fashion, except for encasement. While the customer needs do not specifically mention the mechanisms encasement, it was deemed an important aspect since the placement of the calendar had not yet been determined, and could potentially be placed indoors or outdoors.

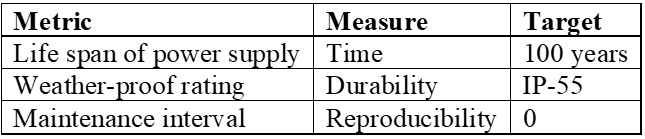

From each of the main branches, we determined what specifics of the customer needs applied to these aspects of the mechanism and branched those off from those aspects. The needs were interpreted further in order to assign units to each sub-branch. These numbers were chosen off of average power consumption values in standard grandfather clocks. The finished design for this project will likely run on a much lower amount of power simply due to the efficiency needed to run the device for 100 years, but these numbers at least provide a rough base line. Moreover, the metric chosen for the tamper-proofing, TL-40, is a standard used in determining the resiliency of gun safes from mechanical and electrical tools. This particular rating insinuates the device can withstand 40 minutes of continuous abuse from typical handheld mechanical and electrical tools. Similarly, the metric for the weather-proofing is based off the international ingress protection scale. The IP-55 rating guarantees a minimal amount of ingress from dust particles, at least not enough to compromise the internal workings, and no ingress of water from small jets of water hitting the encasement from any side. In the end, the device will very likely be hermetically sealed this weather-proof rating should be easily surpassed.

After reviewing the customer needs, it was determined that some of the specific customer needs applied to multiple branches. In order to view the requirements for the mechanism in a more organized fashion, a table was created from the flow chart, as can be seen in Table 3. Since some sub-branches applied to multiple main branches, the main branches were placed in one column at the top of the table and the sub-branches were placed in a column on the left side of the table. The metrics assigned to the sub-branches were placed on the right side of the table. Checkmarks were placed in the boxes where the main elements of the mechanism and the specific requirements matched up in the flow chart. This reorganization allowed for a better understanding of how the mechanism should function.