| Platform Design:

Design Concepts

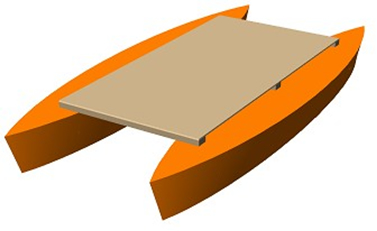

Design 1:

This design consists of a pontoon boat where each one of the hulls will

be made of a different material, one the anode and the other one the cathode.

The hulls will be connected to each other in order to provide an electric

path, and the hulls will be submerged into the electrolyte. The layout

for this design will provide contact with the electrolyte and large surface

area for long lifespan.

Vehicle Design 1

The downside for this design is it has only one galvanic

couple (one battery) and the distance between the materials is large in

relation to the other designs. Therefore the lowest voltage will be provided

by this design. And after the corrosion process that the anode suffers

one of the hulls of the boat will be damaged if not useless, something

that is not cost effective.

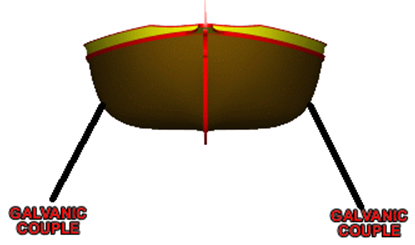

Design 2:

This design consists of a single hulled vessel that will have different

sets of galvanic couples attached to it; these couples will be immersed

in the electrolyte. These sets of galvanic couples will be connected in

series in order to add up the voltage that each galvanic couple provides,

the amount of galvanic couples will be decided according to the needs

of the load that the battery will be powering. The layout for this design

will provide contact with the electrolyte and large surface area.

Vehicle Design 2

The downside for this design is that the vessel will be

unstable depending on the use that it is put into; the single hull does

not provide as much stability as other hull designs. The galvanic couples

could be compromised depending on the speed of the vessel, they can get

stuck or hit other objects because they will be hanging freely.

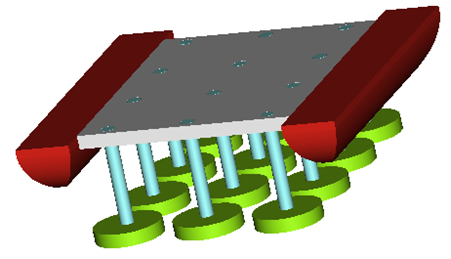

Design 3:

This design is very similar to the previous one but it has some improvements

to it. It consists of a pontoon boat that will have different sets of

galvanic couples attached to it, the rod that is attached to the deck

of the pontoon will be the cathode of the couple and the disk on the bottom

will be the anode, these couples will be immersed in the electrolyte as

well in the moment that the whole vessel is put in it. These sets of galvanic

couples will be connected in series in order to add up the voltage that

each galvanic couple provides, the amount of galvanic couples will be

decided according to the needs of the load that the battery will be powering.

The layout for this design will provide contact with the electrolyte and

large surface area as well as stability for the vessel to perform under

different conditions.

Vehicle Design 3

The downside for this design is that it will be heavier.

The galvanic couples could be compromised depending on the depth of the

electrolyte, they can get stuck or hit the bottom of the container or

environment in which the electrolyte is present.

The past three designs discussed were determined to be impractical for

this application. Designs two and three would create a short circuit since

the anode and cathode materials come into contact with one another. Design

one having only one galvanic couple would not produce enough potential

to power the desired load. Therefore, two new designs had to be created

to meet the needs. Below are designs four and five that are practical

for this application.

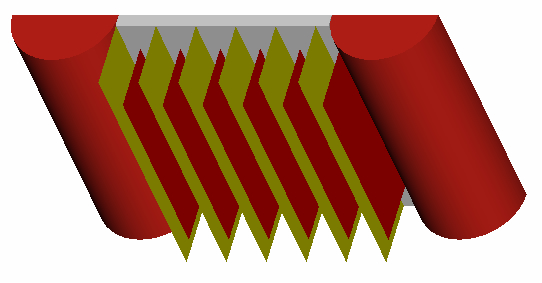

Design 4:

This design uses the same pontoon boat as in design three. The hulls

of the boat will be made of aluminum and the galvanic couple will be sheets

of metal hanging down from the platform. There will be six couples of

an anode and cathode material. This design will eliminate a short circuit

by preventing the contact of the two materials in the galvanic couple.

These galvanic couples will be connected in series to power the required

load. This layout like design three will maximize the contact between

the galvanic couples and the electrolyte.

Vehicle Design 4

The sheets of metal hanging from the platform of the pontoon

boat will have to provide minimum drag force to ensure its efficiency.

The weight of the sheets will also have to be minimized to prevent buoyancy

failure.

Design 5:

Design five was based off a recommendation from the project advisor Dr.

Dave. This design is a pontoon boat that uses the hulls of the vehicle

covered with galvanic couples. The hulls will have alternating materials

of the anode and cathode attached. There will be a minimum space between

each material that will be filled with insulation to prevent a short circuit

between the materials. This design will reduce the amount of drag force

because there will be nothing hanging down from the platform of the design.

Below is a built prototype of this design.

Vehicle Design 5

This design was built to get adequate test results for this

design. The surface area exposed to the electrolyte will not be enough

to provide a long lifespan, because only one of the faces of the plate

is exposed to the electrolyte. The wiring with this setup becomes increasingly

complicated in order to avoid leaks inside the hulls and completely sealed

connections between the circuitry and the couples. On the other hand the

drag forces exerted on this design are minimal having in mind that the

plates are shaped exactly to fit around the hulls.

Design Concept Selection:

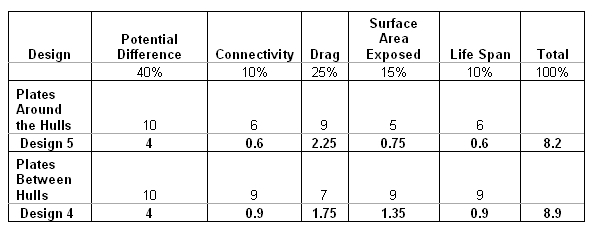

The design selection is between design concept four and design concept

five. A design matrix was created to compare each design vs. five parameters.

The five parameters were: potential difference, connectivity, drag, surface

area exposed, and life span. The potential difference was the most important

parameter and had the largest weight in the final decision. The second

most important parameter was drag because if the drag was too high it

would counteract the power produced. Below is the decision matrix in the

following table.

The design matrix concludes that design 4, plates between hulls, just

barely outweighs design 5. Both designs produced the same potential difference;

however design four has a longer life span. Design 5 eliminates some of

the drag, however it is not significant enough to change the results presented

in the design matrix. The final design was concluded to be design 4.

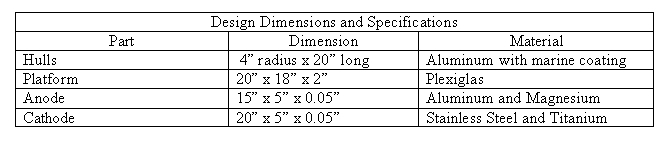

Design Specifications and Calculations:

Vehicle Design

A small scale prototype of design four had to be designed to accurately

replicate the design. The following table is a list of dimensions that

were estimated and then equations were used to prove that these dimensions

would meet the demand of the vehicle.

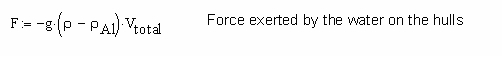

The maximum load that can be sustained by the platform was calculated

to determine if the dimensions of the pontoon boat were accurately estimated.

The following equation was used.

The maximum load was calculated to be 27.51 kg.

|