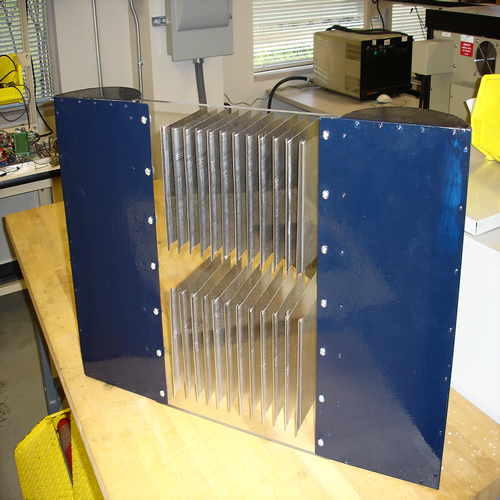

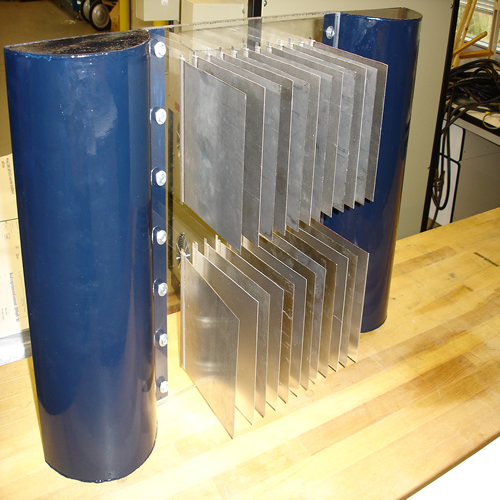

| Final Design:

The following pictures show the final design that was

built for the demonstration that will take place at the Open House on

April 6th 2006.

The demonstration will allow the observer to see the output

of the different materials selected and a simulation of the booster circuit

that will be implemented on the system.

Conclusion

The final design was chosen taking into consideration all the experiments

performed and having in mind the background research on all decisions.

The final design is composed of a pontoon boat that serves as a platform

for the autophagous battery pack, the autophagous battery pack, and the

circuitry of the system. The galvanic cells that integrate the autophagous

battery pack are made of a pair of 7”X7” metal plates that

hang form the deck with a thickness of 0.05” (gage 18). The metals

used are Aluminum 3003 and Magnesium Alloy AZ31B as the anodes and Stainless

Steel 304 and Titanium 6al-4v as the cathodes of the galvanic cells respectively.

The galvanic corrosion between the Magnesium Alloy AZ31B and the Titanium

6al-4v provided the greatest potential difference as well as a constant

output. This couple is not efficient for a long duration due to the quick

corrosion rate of the Magnesium Alloy AZ31B.

The setup of the final design minimizes the distance between the plates

without short circuiting the connections and provides enough space for

more than one galvanic cell. The surface area of the cathode is the same

size as the anode, this way the corrosion rate is at an acceptable level

and the potential difference is maximized.

The potential difference of one galvanic couple was too small to power

a desirable load. Even with a conditioned circuit, the available power

would be minute. Having several integrated circuits that putted the galvanic

couples in series would increase the power, and should be further investigated.

Galvanic couples provide a depletable energy source, however the efficiency

of the galvanic couples as a power supply in minor due to the small potential

difference. Galvanic couples should not be used as the primary power supply

because the amount of couples need would outweigh the benefits of the

amount of power supplied. Galvanic couples would be efficient as an emergency

back up supply for a device that required a small amount of power such

beacon signal or GPS transmitter.

This project demonstrates the potential difference between the four galvanic

couples tested: Aluminum 3003 and Stainless Steel 304, Aluminum 3003 and

Titanium 6al-4v, Magnesium and Stainless Steel 304, and Magnesium and

Titanium 6al-4v. The four galvanic couples were inserted in the pontoon

prototype and show the observer the potential difference when changing

the galvanic couple. A simulation of the circuit design also shows the

increase in power supply when the circuit is conditioned.

|