Throughout our concept generation process, several methods

of thought were used. To start, we utilized biomimicry across multiple

concepts. The idea of biomimicry uses ideas present in nature and applies them

to design advancements. By studying strategies found in nature, efficient and

unique solutions can arise. Concepts such as a 3D printer encased in a turtle-like

shell with 4 legs for movement pulls ideas from observing nature’s organisms.

The crap shoot method allows for more unpredictable and wild

design concepts. Although these concepts are generally not implemented, parts

of these concepts can be very useful. This process removes the limit on

thinking. An example of crap shoot concept generation in our process is a

hovering additive manufacturing printer that has an electronic leash mode to

follow the user wherever it goes.

Another process that was implemented was the morphological

chart. A morphological chart is a tool that combines various parameters of a

problem. This allows for unique solutions through the combination of different

attributes. A group of ideas used were: aluminum for weight, a solar power

reserve, a vibrating filter (combo with angled filter and/or electromagnetic

filter), input powder filter to maintain necessary powder particle size, and carwash-style

brushes to remove excess powder from print (combo Powder Bed Fusion (laser)).

The anti-problem method is a strategy that focuses on what

would make the problem worse rather than what fixes the problem. By considering

the negatives of the problem, a new perspective is attained. This perspective invites

direct solutions. In additive manufacturing,

gravity is a key feature of the process. The Psyche asteroid has extremely low

gravity at about 1.5% of Earth's. This method of thinking led to concepts such

as a rotationally induced gravity additive manufacturing device.

Brainstorming was the main concept generation strategy

employed during the process. The brainstorming process is an

open discussion to invite creativity and collaboration. Each idea is suggested

without assessing its quality. This allows for a large volume of suggestions

which can be narrowed down to plausible ideas. An example of a concept

generated by brainstorming would be a system that uses powder bed fusion to

melt powdered metal in layers to print an object out of metal.

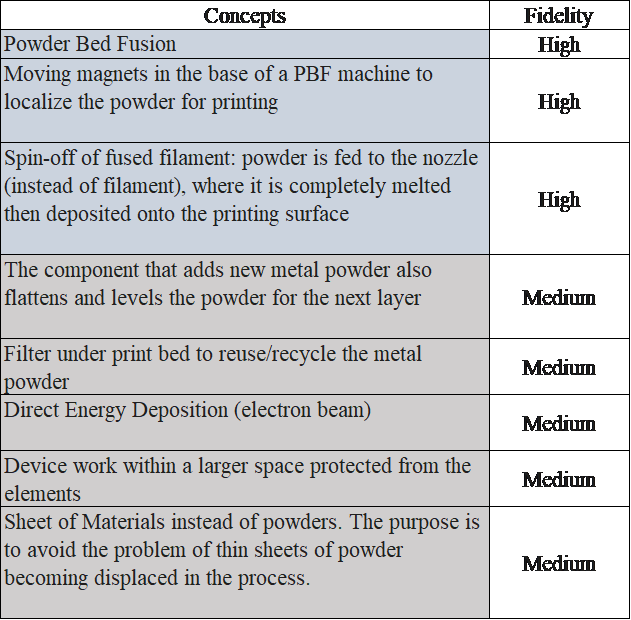

Using the methods mentioned previously, over 100 concepts were generated by the senior design team. The team was able to narrow down the list to 20 concepts with the highest fidelity by discussing plausibility. This was a collaborative effort and all concepts were discussed. After narrowing down the list, the team utilized a Google Forms survey to vote on the highest fidelity concepts. The 8 concepts with the best scores were decided to be the high fidelity and medium fidelity concepts chosen for more serious consideration of the concept selection stage of the project.

After the initial concept generation phase, the team was

left with over 100 concepts. Some were

highly feasible; others were not. The

team leveraged an internal survey based on engineering intuition, also with consideration

of customer requirements and prototyping restraints, to reduce our focus to the

more highly feasible options. There were

five concepts with medium fidelity: concepts that would solve the problem at

hand but have questionable aspects that deem them less likely to pursue during

this project.

The first medium fidelity concept is a powder bed fusion

device that uses a system to combine two of its functions. It would add a new powder layer to the

printing volume while simultaneously leveling it. This concept introduces new design

considerations such as feeding powder through the system, precision leveling,

and gravitational effects. While it

could be an innovative concept to build on, it does not cover the whole scope

of the project.

The second medium fidelity concept is a filter positioned

under the base of a powder bed fusion device that recycles powder as it runs

through multiple prints. It would sort

the particulates that remain in usable form, rejecting powder that has been

fused into larger pieces during the previous printing cycle. It is an innovative idea to be considered

during the concept selection and prototyping phases, but it does not cover the

whole scope of the project. This concept

also introduces a lot of moving parts that could jam with fine particles moving

through them.

The third medium fidelity concept explores using direct

energy deposition as the mechanism for additive manufacturing with metals. Instead of using a laser, this concept uses

an electron beam to heat the input material to its melting point. It is medium fidelity because the use of an

electron beam poses a great risk to the device’s operation in space. Additionally,

the traditional methods of direct energy deposition produce outputs with lower

precision and rougher surfaces than other metal additive manufacturing

processes.

The fourth medium fidelity concept is protecting the

additive manufacturing device with an outer shell. It considers the radiation and particulates

the device would experience in the environment on Psyche. It controls the conditions inside the shell

ensuring the device will operate under ideal, steady conditions. A limitation of this concept is its

accessibility. It complicates the input

of new materials and the retrieval of any parts the device creates.

The fifth medium fidelity concept is a device that uses sheets

of metal as inputs, instead of powders.

This concept avoids the problem of thin sheets of powder becoming

displaced as they interact with the heating element. However, acquiring conditioned sheet metals

for inputs on the surface of Psyche would be quite complicated.

High fidelity concepts are the most polished and feasible ideas

given the scope and specifications of the project. These are ideas that the

team felt would have the highest possibility of mission success. The three

highest scoring concepts from the survey were decided to be the high fidelity concepts

of the project.

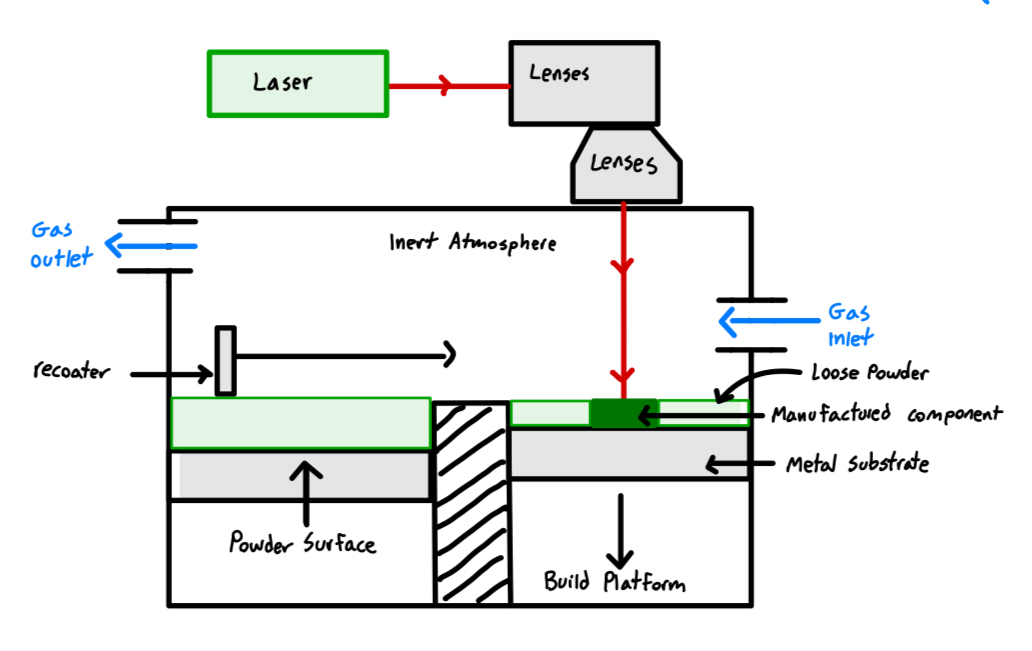

The first high fidelity concept is a powder bed fusion (PBF) device which is the most widely used metal AM process on earth. The design that team most closely resembles a selective laser melting process. This method is applicable to the metals expected to be on Psyche. PBF is also the most researched and understood method for AM of metals, making it highly fidelity concept. The system will spread a thin layer of metal particle powders across a metal plate printing bed then use a high precision laser to fuse the powdered metal particles into desired geometry. Since PBF machines weld the part to the metal bed, the design will need to remove the part from the plate. In complex geometries, support structures also may be needed which would need to be removed later.

After the print is completed, post processing is needed before the manufactured parts can be used. The process of spreading thin layers of metal powder will result in large volumes of powders and removing these needs to be done carefully as metal powders can be flammable or combustible. This can be done using a vacuum or electromagnets. The second process is removing the welds between the metal bed and the part. This may be tricky considering the limited volume of the design. This could be done using another laser that is tangent to the metal plate or maybe sawing them off. Next, any support features will be removed as well. This could be done by cutting or drilling the supports. Additional features that the PBF may include heat-treating the part. The system could be prepared to act similar to a furnace or temperature chamber to accomplish it. Heat-treating may be hazardous because of the possibility of flammable powders that weren’t removed. Another option would be to use the extreme heat from the sun rays to sunbake the parts before use. These parts typically have rough surfaces so having a way to smooth them out may be critical to the effectiveness of the part as well.

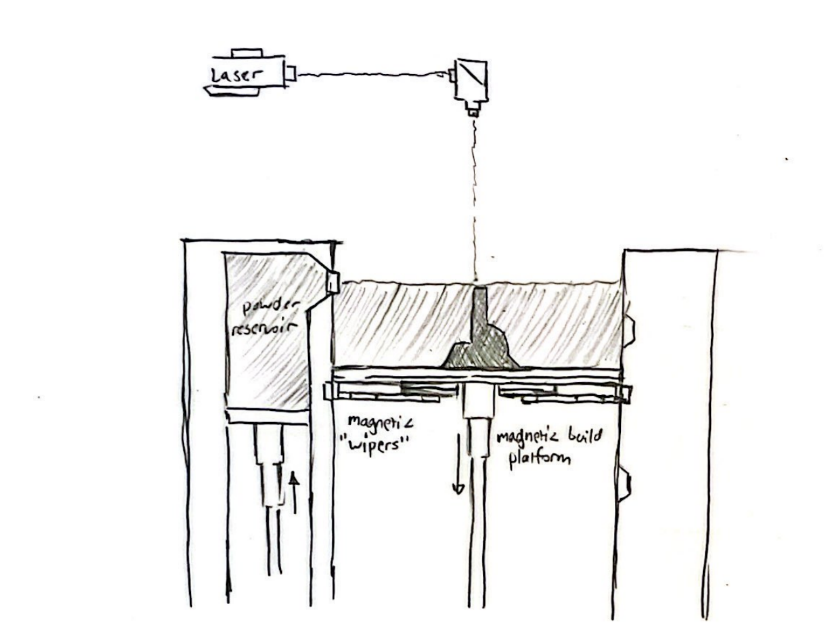

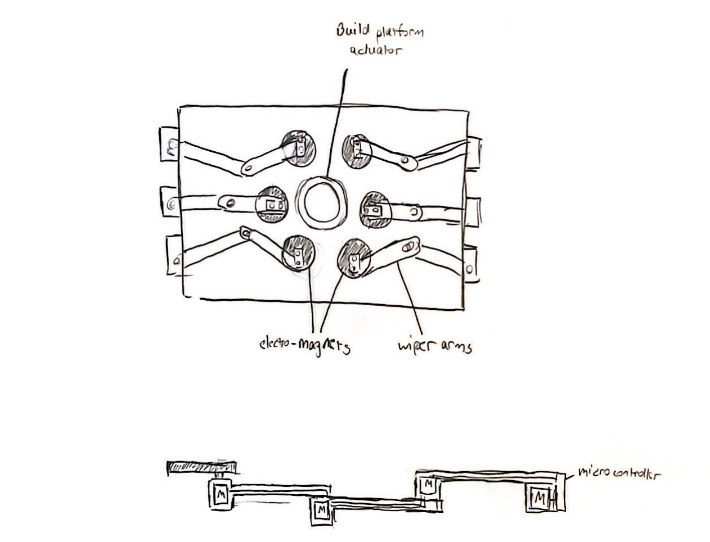

The second high fidelity concept is a powder bed fusion AM

system that seeks to solve the issues posed by the weak gravity of Psyche. This

design aims to leverage the magnetic properties of the most abundant metals

found on Psyche, nickel and iron. Powder bed fusion ordinarily relies on

gravity to fill the print bed with metal powder and then smooths over the printing

surface with a roller/sweeper. The top surface of the print bed must be as

uniform as possible in each cycle to ensure that each layer is the right

dimension and to prevent structural weaknesses in the final product.

Since the gravity of Psyche is very weak compared to that of

earth, this design aims to use magnetic forces to ensure the powder in the print

bed does not become suspended for extended periods of time or shift

dramatically during or after the smoothing process. The concept uses an electromagnetic

print bed to attract the metallic powder towards the bed. The magnetic force

will act as a substitute for gravity, needing only to be strong enough to attract

powder at the top of the printing vat. To assist with ensuring the critical area

of the print surface remains level, a set of motorized arms with electromagnets

will move beneath the print bed ensuring that the powder in the critical area is

tightly packed and evenly spread.

During the powder spread phase, the reservoir will deposit powder

into the printing volume in a localized area where it will be attracted towards

the print bed. The mechanical arms will use their smaller electromagnets to

spread the powder across the entire printing volume. Next they will move to the

critical area of the printing volume to ensure the space is evenly distributed.

Afterwards, the roller/sweeper will smooth the surface of the print volume,

ensuring that it is ready for the laser fusion stage.

The size of the magnetic field must correlate with the size

of the print volume. The magnetic force will exponentially diminish with

increasing distance from the electromagnet. This will place strict limitations

on the size of the print volume based on the energy and size restraints on the

electromagnet used in both the print bed and arms.

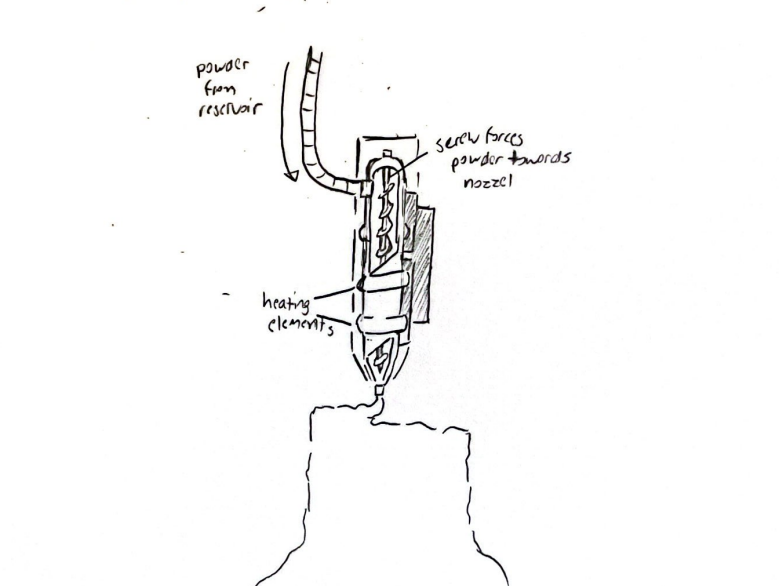

The third high fidelity concept is an adaptation of a more traditional additive manufacturing process used for plastic products. Due to the issues posed by microgravity and vacuum conditions, a traditional extrusion method where the input material can remain contained and separated from the printing volume would be of great value. In this method, no reservoir material needs to enter the printing volume prior to melting. Fused granulate extrusion traditionally uses plastic pellets that are heated up as they are moved downwards by a screw and finally extruded as a filament-like material through a nozzle. The nozzle moves about the printing volume extruding plastic filament layer by layer building the desired output from the bottom up

This concept would adapt fused granulate extrusion by using metal powder in place of plastic pellets. Metal powder housed in an external, sealed reservoir would be pushed into an extrusion chamber that houses multiple heating elements as a motor-driven screw forces the powder down towards the nozzle. By the time the powder reaches the nozzle, the combination of pressure and heat would liquify the metal at the nozzle tip so that it can be extruded. The nozzle and extrusion chamber would then move along the desired path layer by layer to form the output.

This site was created with the Nicepage