Project Description

Our project is to design a kite system of relatively simple design and construction that produces usable electricity. The system should be comprised of off the shelf parts in order to make the system relatively expensive and economically attractive. By being of relatively simple design, the system would be simple and straightforward to maintain which will minimize the service costs and increase the overall time in service of the system. This system will utilize a single kite to generate electricity in order to eliminate the need for complex and expensive flight controls.

To generate power, the kite will be tethered to a permanent magnet within a housing that contains an electric coil. As the kite is subjected to a wind load, it will pull the magnet through the coil. When the load decreases, a spring will force the magnet back through the coil housing. Electricity is generated eac time the magnet passes through the housing. The kite will also collect water from moisture in the atmosphere. The kite will condense the moisture and send it down a tether to an aquifer at the base.

Conceptual Design

Conceptual Design

The conceptual design that was developed has the winch system in the air with a string attatched to each end of the kite. The strings come together inside the winch and one string is sent to the ground that is connected to the magnet inside the solenoid. The advantages of this design includes that all the tension goes into one string so the force of the kite will easily make the string taught and pull the magnet inside the solenoid. There is minimal surface area covered on the ground by the housing and there is minimal hardware being used. The disadvantes includes that the winch is up in the air which creates complications when maintenence or repairs are required. It also has little yaw control which is the rotation around the vertical axis.

Helium will be used to initially lift the kite from the ground until the force of the wind is capable of keeping the kite aloft. Once the kite is bale to remain in the air on its own, the helium discharge will retract. When aloft, the helium will only unfold if insufficient wind forces fail to lift the kite.

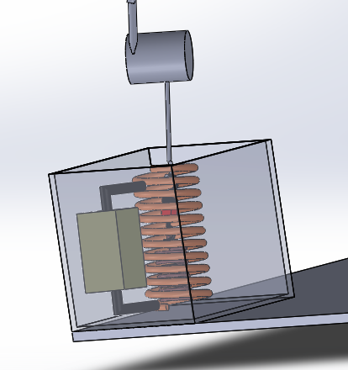

The power generator consists of a housing that surrounds the mechanical comonents. Inside the housing is the solenoid that the magnet will be passing through. A spring will be fixed to one end of the housing with the other end connected to the magnet. The magnet, which is connected to the kite tether, will be pulled through the coil as the kite is subjected to a wind load. As the wind load decreases, the spring acts to restore its natural state by forcing the magnet back through the coil housing. The housing will be attatched to a swivel, allowing the housing to spin on its axis depending on the direction of the wind and the flight path of the kite. Wires are attatched to both ends of the coil that are connected to a rheostat, which controls the current. The rheostat is then connected to an inverter, which converts the DC power to AC so it can be delivered to the power grid.

Close up of power generator and housing

Demonstration Model

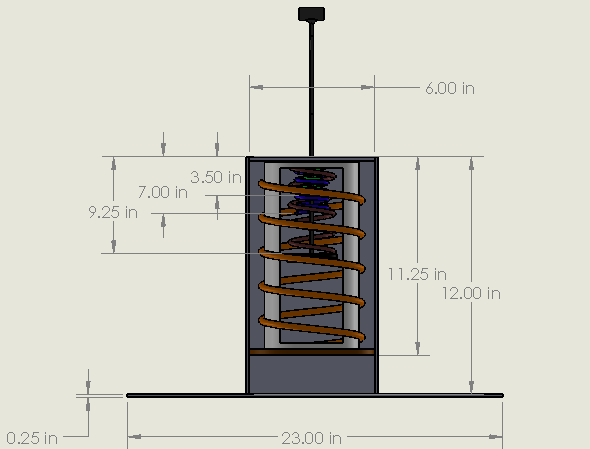

The demonstration model was designed to be a scaled down version of the concept model that could be used to show proof of concept. It consists of an aluminum housing with dimensions shown in inches in the figure to the right. The design included compression springs instead of tension springs. This was done because compression springs were seen to be safer and less likely to get damaged. Three concentric springs of different lengths and spring coefficients were used to increase the amount of spring force being applied down on the magnet the farther up the kite pulls it. The magnet is attatched to the bottom of the longest magnet and to the kite via kite string. The magnet and springs sit inside of the solenoid housing which has the copper wire wrapped around it. The magnet is pulled up when a force is applied by the kite and is then pushed back down by the springs. This creates an oscillatory motion of the magnet which is crucial in generating electricity. One other design of the demonstration model included a DC motor connected at the top of the base housing. This motor was used instead of the kite to pull the string in a motion that would simulate an optimal scenario of pull from the kite.

Front View of Demonstration Model