October 25, 2014

Design Specifications

Below, a full list of specifications and objectives for the magnetically coupled pump system can be found, as well as the selected design for the project.

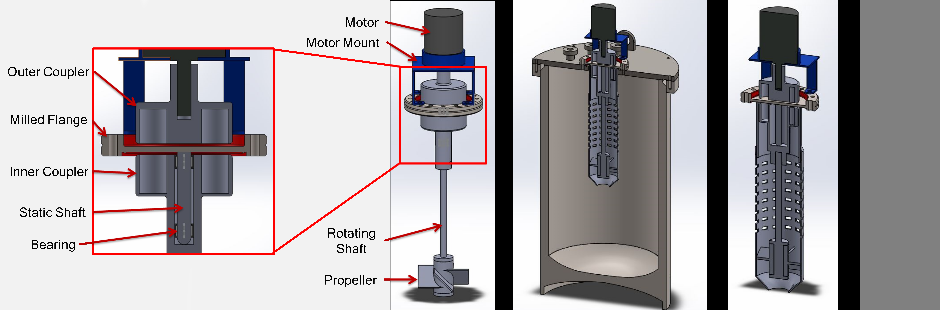

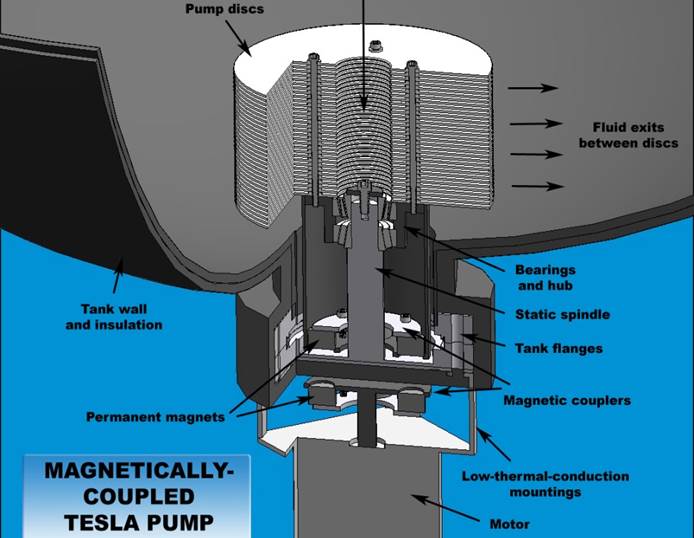

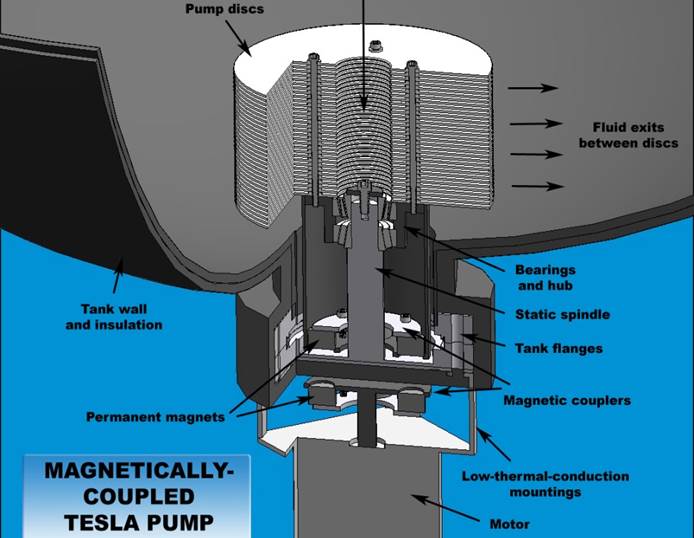

Instead of using a tesla pump to mix the cryogens, a centrifugal/axial pump will be used. The decision matrix as well as the analysis of the design concepts can be found in the Midtern I Report.

Read more

October 20, 2014

Design Specifications

The design specifications can be broken down to the tank specifications and the

requirements that must be met by the motor-pump system. The cryogenic tank that will be used in the project is the

Cryofab CF 1424-F cryostat.

The cryogenic propellants must be stored at the low pressure of 15 to 25 psia. In order to prevent the pressure

from rising, the mixer will make the temperature homogenous to prevent the cryogen from boiling. The heat will also

be limited through the use of 0.5 in of foam and 20-30 layers of MLI (Multi-Layer Insulation) where necessary.

The motor-pump system must be fitted to a 6” ConFlat flange made of stainless steel.

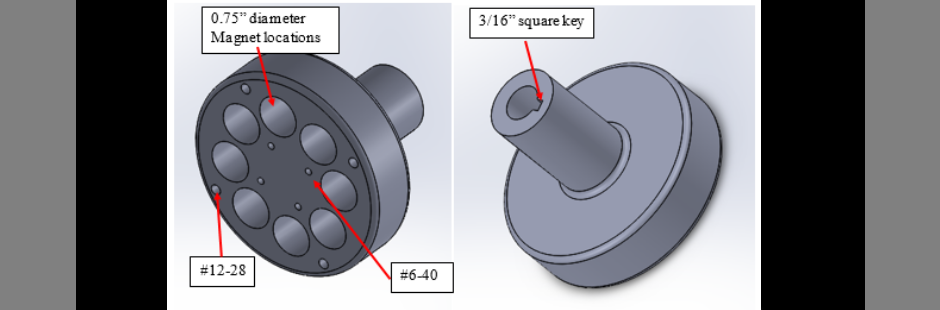

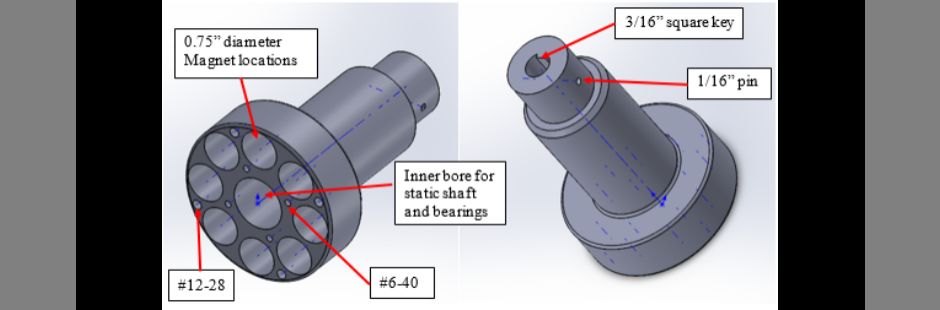

The flange can be milled to 1/10 inch in thickness to guarantee that the magnets can sufficiently couple through the

flange. The seal mechanism is a knife-edge that is machined below the flange’s flat surface. These knife edges make grooves

in the opposite side of the gasket as the flange-pair is tightened thus yielding a leak-tight seal. A copper gasket or indium wire will also be used to

completely seal the cryostat. The flange has a 4 inch port into the tank, therefore the entire apparatus inside the tank must not exceed

4 inches in diameter. Six to eight magnets will be used for the coupling on the magnet plates.

The pump/mixer must reach 12 inches into the tank to ensure that the fluid be thoroughly mixed. The design will look similar to the layout on the right.

Page 3 of 312 3»