|

|

Team CERN

Collaboration

with Romania

|

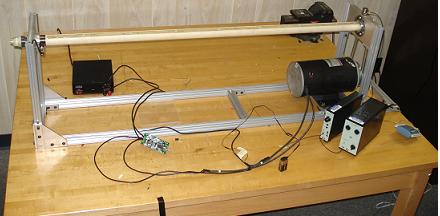

The D3 Balance Detection Machine

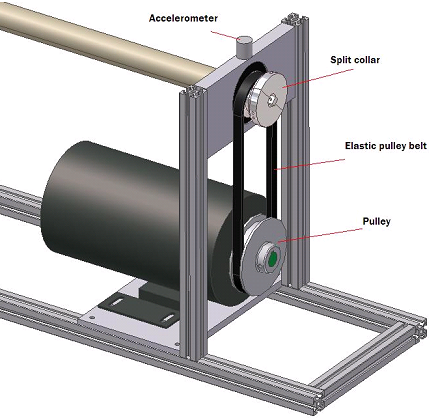

design has evolved into the form shown in Figure below.

It remains largely the same as the original D3 Balance

Detection Machine concept, however, several

modifications have been made in its development. 80/20

extruded stock is used throughout the assembly as a

framing system, with components bolting onto the frame

using L-brackets (not pictured). The machine may be

bolted down to a table for stability while in use.

Figure – Balance Detection Machine, pictured with 1.2m

long shaft segment

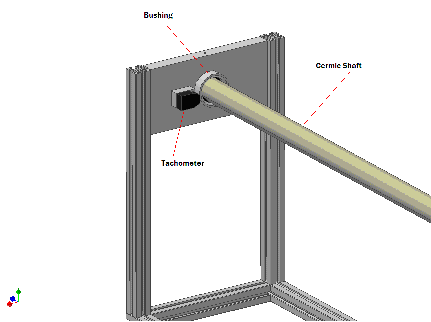

Regarding the left side of the

machine (see Figure below), the mounting block provides

support for sensor positioning and bearing housing. The

rotary sensor (an optical encoder) provides data for

rpm. The accelerometer (not shown, mounting hole shown

on top surface of plate) detects radial acceleration,

which will be used to derive radial displacement, of the

shaft under rotation. Both sensors are bolted to

brackets connected to the mounting block.

Figure – Left side of the D3 Balance

Detection Machine

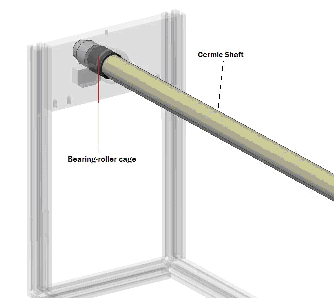

The center of the mounting block

has a bushing to allow for the ball bearing to fit

inside it (see Figure below). The flange and bearing

(parts (a) and (h) from Figure of the side view of

ceramic shaft ) will remain connected to the ceramic

shaft and used to mount the segment on the machine. For

shorter length shafts, the motor and bearing-plate

subassembly may be translated down and marked on the

base frame for consistent repositioning in the future.

The left side of the machine will remain fixed, making

calibrations for both configurations easier.

Figure – See-through view of left side of Balance

Detection Machine

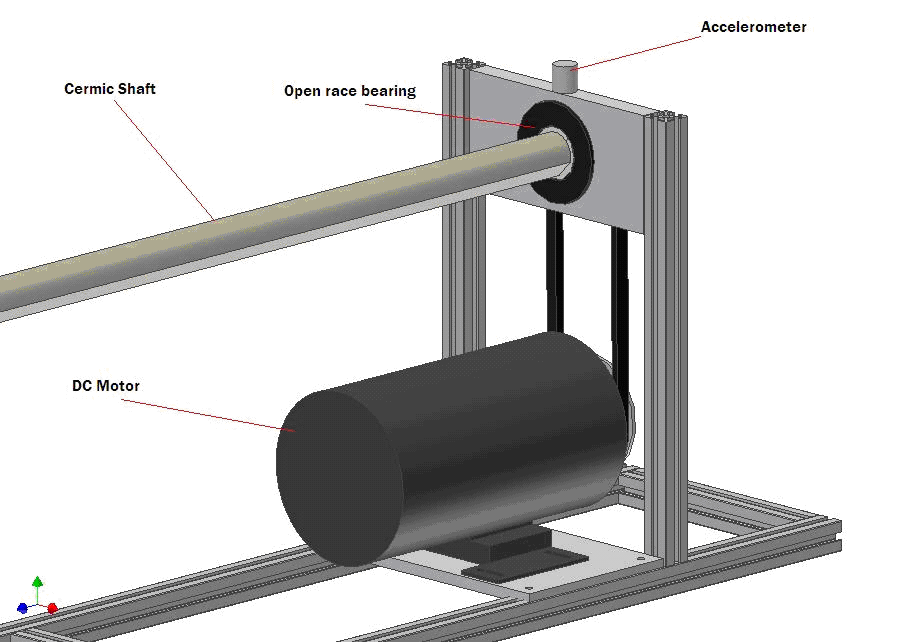

Regarding the right side of the

machine (see Figure below), the bearing-plate houses the

open-race bearing and provides a mounting surface for

the accelerometer. The open-race bearing is press-fit

in the plate, and the sensor is screwed into the top

surface of the plate. A split-collar is positioned over

the shaft, slid into the bearing, and is used as a

pulley, ultimately connecting to the motor. The motor

itself will be regulated by a motor controller, which

has a live readout on the Lab View program developed by

the Romanian team.

figure – Right side of Balance Detection Machine

The split collar (which also acts

as a pulley) connects to the motor by a pulley system

(shown in Figure below). Pulleys are mounted on the

motor drive-shaft and the ceramic shaft, transmitting

power from the motor to rotate the shaft segment.

Figure – Right side of Balance Detection Machine showing

pulley system

The following is a description of

the reasoning used to select components used in the

Balance Detection Machine. The Romanian team is

exploring sensor selection at time of writing, hence

only descriptions of required specifications are

included here.

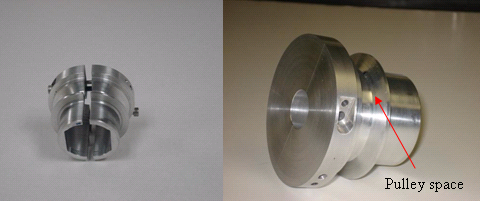

The split collar is one of the

most sophisticated mechanical components of the whole

assembly. It is specifically designed for this

application. The inner surface matches the cross-section

of the shaft. The outer surface is designed to have a

slip fit with the bearing. The split collar is also

machined to act as the pulley that connects the shaft to

the motor. Once attached on the shaft the two halves are

bolted together. The inner surface is also machined to

go around and not touch the inner components of the

shaft.

Figure -

Split Collar

The

bearing is an open ball bearing designed for high speed

applications. It has an 85 mm outer diameter and it fits

45 mm diameter shafts. The bearing can handle up to 8800

Maximum RPM. As shown in the picture the bearing was

press-fit into the bearing plate.

Figure - Bearing Plate

Pulleys

The

pulley that is mounted on the Motor shaft is a standard

V-belt drive Pulley purchased through McMaster-Carr,

with a 10.16 cm outer diameter. The other pulley is

enclosed in the split collar and it has a 6.0 cm outer

diameter. The diameters of both pulleys were

specifically designed to be different so the motor

vibrations can distinguished from the mass imbalances of

the shaft when doing the FFT.

Drive Belt

The belt

is made out of thermo-plastic and it can be welded

together for the desired length. It is 0.95 cm in

diameter and 65.56 cm long.

Figure - Pulleys and drive belt

The

supporting frame is relatively simple. It consists of

80/20 railings cut to precision and Aluminum plates that

the shaft and electric motor rest on (see picture). The

frame is assembled together with L and T brackets. Since

most of the material is Aluminum the frame is light

which allows for extra mobility, but it will need to be

bolted down to a much heavier platform so no extra

vibration is induced.

The motor is very robust, total

power being rated up to 1 Hp. At full load it draws up

to 41 Amps of DC current and a potential of 24 Volts.

However it will never reach these specs because it is

limited by the power supply (see below). One of the

advantages of this motor is the weight, being the

heaviest component of the whole assembly, which helps

with damping the system. Also very little vibration

comes from the motor, even when operated at high

frequencies. But to minimize the motor vibration even

more a damping material is places in between the motor

and motor plate. One little disadvantage is that it is a

little noisy when operated at low frequencies.

Figure – One horsepower motor

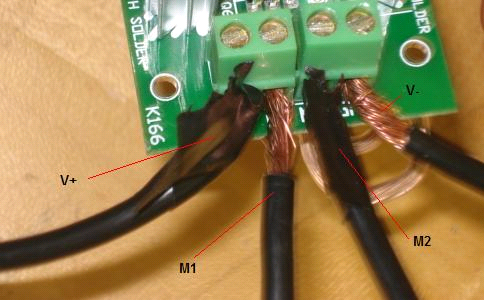

The motor

controller was bought as a kit and put together by

soldering all the components to the PC board. Originally

the controller was rated 12-32 Volts DC at 5 Amps, but

some modifications were made by adding 16 Gauge wire

through to the mosfets channels (see picture). With this

modification the controller can handle motors rated up

to 47 Amps. Motor speed control is done by manually

rotating the potentiometer. Also a nice feature although

not required about this controller is that it allows

bi-directional rotation.

Figure – Motor controller configuration

The motor

power supply was bought directly from

Radioshack

store. It outputs up to 15 Amps at 13.8 Volts DC. The

nice feature about this Power Supply is that it plugs

directly into the wall outlet, eliminating the need of a

battery source. Also the On/Off switch can be used as an

emergency power cutoff.

Figure – AC/DC Power supply

*The following electronic

equipment was borrowed from Dr. Patrick Hollis for

running the experiment. Once shipped to CERN, similar

Equipment will be purchased for the machine.

The

accelerometers are Bruel

& Kjaer brand, type 4381. It is a high sensitivity

piezoelectronic charge accelerometer (98 pC/g) that can

be used for low frequency measurements. It is being

powered be the Sensor power Supply that connects through

the Charge Amplifier.

Figure - Accelerometer

The

Photoelectric Tachometer is Bruel & Kjaer brand as well,

Probe MM-0012. It can be powered up by simply connecting

it to a 9 Volts battery. The BNT cable that connects to

the tachometer was modified so it can be connected to

the battery and the DAQ. The tachometer emits a infrared

light that is reflected back by a reflective strip

attached on the shaft. Also the distance between the

tachometer and reflective strip was minimized to about 4

mm for better feedback.

Figure - Tachometer

The

Sensor Amplifier is also Bruel & Kjaer brand, model

2651. It enables a charge amplification of up to 10x.

That way the sensitivity of the accelerometer can be

increased up to 980 pC/g. It also connects the

accelerometers to the DAQ and Sensor Power Supply.

The

sensor power supply powers up the accelerometer and

Charge amplifier, by simply plugging it into the wall.

It caries a Bruel & Kjaer name brand as well.

Figure – Power supply and Charged Amplifier

The Data

Acquisition Board (DAQ) transmits the accelerometer

signal to the computer where it can be further analyzed.

It is Computing Measurements brand model USB-1208FS. It

connects to computer through USB cable and has an up to

12 bit resolution. The scan rate is 50,000

scans/second.

80/20 manufactures industrial

erector sets, t-slot extruded stock that may be used for

quick assembly of machinery. The stock is made from

6105-T5 Aluminum, and is readily available through

industrial suppliers such as McMaster-Carr or Reid

Supply. A whole line of accessories are sold for the

stock as well, including T-nuts and L-brackets,

necessary for bolting frame pieces together. At $3.35

per ft from McMaster-Carr, it is ideally suited for this

application.

Copyright

2007 CERN Team USA Group 13 Inc. All rights reserved. |