|

The

coil leads were split and extended so slip-rings could be connected to the

coil in parallel (figure XX, left). |

|

The

wires were fed through the appropriate radial holes out to the large hollow

end of the shaft (figure XX, center |

|

The

coil was carefully pushed into the shaft and aligned with its mounting

holes. The mounting screws were tightened to secure the coil

tangentially to the inside of the shaft wall (figure XX, right). |

|

Next,

the shaft was mounted in the bearings (figure XXI). The AC4598

slip-ring had to be mounted first because it lies in between the two

bearings. It was not, however, secured to its base yet. Instead,

the wires were taped securely to the shaft to prevent the slip-ring stator

and rotor from rotating relative to one another.

The encoder was mounted and secured to the shaft. The

CAY-731 and SM-050 slip ring rotors were also tightened to the shaft. Their

stators were not yet mounted, to prevent premature wear of the brush/ring

contacts.

The

motor was mounted to the 8020 frame and aligned with the shaft. Alignment

was accomplished using levels, straight-edges, squares, and visual

observation.

|

|

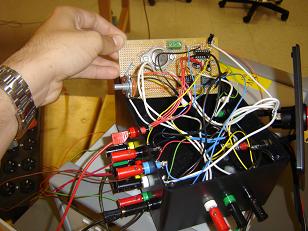

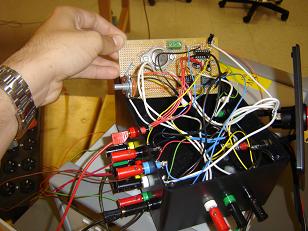

The

electronic circuits (figure XXII, left) and wiring box were fabricated

(figure XXII, right). |

|

After alignment and initial testing, the CAY-731

and SM-050 stators were attached to their respective rotors (figure XXIII).

The stators hold the delicate brushes that contact the rotating rings of the

slip-rings. |

| |

Finally, the components were wired appropriately,

according to table II.

|