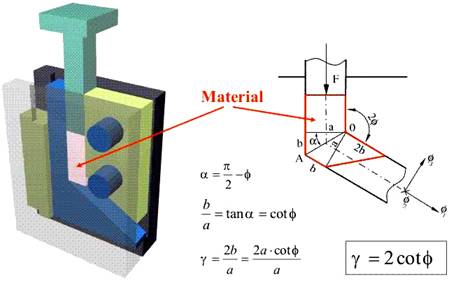

ECAP concept:

Equal Channel Angular Pressing (ECAP)

is one of the discontinuous processes of Severe Plastic

Deformation (SPD). A sketch of such a tool is depicted

in Fig. 2.1. Included in Fig. 2.1 is the mathematical

terms that describe the development of ??, the Shear

strain.

Figure2.1: Typical ECAP tooling apparatus.

[1]

The concept behind the tooling consists

of two intersecting channels of the same cross section

that meet at an angle 2? (see Fig.2.1). The geometry

of the tooling allows for material deformation by

simple shear. The cross section of the specimen remains

equal before and after a processing step, thus it

is possible to subject one specimen several times

to ECAP in order to reach high levels of plastic deformation.

A circular or squared cross section of the channel

provides the possibility of a materials processing

at different routes that are distinguished by their

different combinations of sample rotation around the

channel axes between consecutive processing steps.

The processed sample will undergo some changes, mainly

a distortion of grain size. Repeated processing to

form smaller grain sizes breaks down the deformed

grains. In addition, the unique deformation path (shearing)

changes the structure of the material to make the

metal respond in a unique fashion to recrystallization.

It has been observed that the grain structure in ECAP

material after heat treatment has been refined and

is much more uniform. Grain refinement and uniformity

of grain size are desirable characteristics in controlling

mechanical properties of metals.”