Home Ergonomics SAE Competition Background Design Construction Products Purchased Testing Final Product Links

Construction:

Seats:

The seat we have chosen to use is the aluminum shell with molded

fiberglass inserts because it has the most adaptability and durability.

To help reduce the cost that an individual seat for each person would

cause we will use two different inserts to accommodate small and large drivers.

The seat is manufactured by making an aluminum shell. Then make the two-part foam and pour it into a large plastic

bag. To make the foam, prepare the

two-part foam in separate mixing cups. The

foam works the same way as epoxy glue both proportions have to be the same to

ensure the final compound will work properly.

When the two parts are ready then you have to mix them thoroughly.

Have the driver sit in the car on the bag and let it dry. The driver must not sit down to early or the foam will result

in the driver’s weight spreading the foam out with nothing left underneath to

support him. If the driver waits

too long the foam will be too hard to mold.

To make sure that we perform this correctly we mixed a small batch to

test when it is a good time to sit down. Once

the foam has dried, you must shave of any excess foam.

After it is dry, the next step is to apply the fiberglass.

Figure

10: Mixing and pouring the Polyeurethane foam

Figure

11: Applying and sanding the fiberglass layer of the seat.

The figure above shows the process of applying the fiberglass layer to

the seat. First, the seat must be

painted with the fiberglass resin that comes with the fiberglass kit.

Then, the fiberglass sheets must be laid on top of the resin.

The resin is then painted over the top of the fiberglass sheets.

The combination of the fiberglass sheets and resin for a hard layer over

the foam to ensure that the foam does not crack.

After the fiberglass has dried, the next step is to spread Bondo over the

fiberglass and sand it down. This

step is performed in order to ensure that the seat does not have any rough edges

or cracks in the fiberglass. The

Bondo is applied to the fiberglass and left to dry for approximately thirty

minutes until it is hard. The Bondo

then has to be sanded smooth so the seat can be primed and painted.

Figure 12: Final product before painting

Figure

13: A close up of the final product of the dashboard

Figure

14: Picture of the final product of the dashboard with the steering wheel off

The figure above shows a picture of the dashboard from a distance. It is easier to see the blue tint in the carbon fiber when looking at this picture versus the other one. The blue adds a great custom and appealing look to the car that most car do not have.

The figure

above shows a picture of the dashboard with the steering wheel attached. The picture shows how the driver will be able to see all the

gauges over the steering wheels at all times in case of any car trouble that

could occur. The gauges from left

to right are as follow; water temperature, fuel pressure, and oil pressure.

We chose to put the fuel pressure gauge in the middle because we believe

that it is the most important to our vehicle.

The

driver will also be able to see the switches through the center of the steering

wheel even though it is not necessary for them to be visible.

The switches just have to be easily accessible to the driver at all

times. The switch on the left is

the kill switch, which will shut of the engine instantly in the case of an

emergency. The button on the right

is the starter button, which starts the car only when the kill switch is flipped

to the on position.

Formula

Shifter:

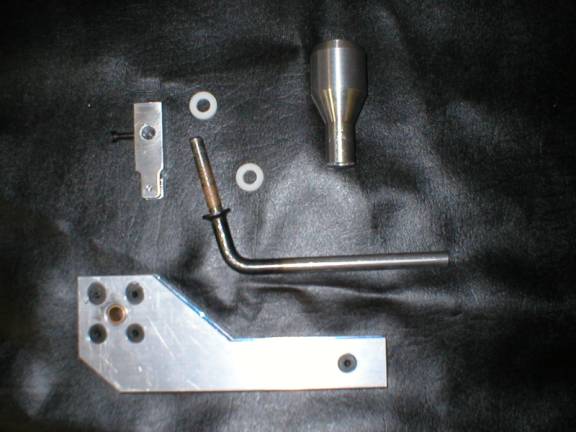

Figure

16: Picture of the formula shifter disassemble

All

of these parts were designed and manufactured by the group in order to fit the

formula car perfectly. The parts

are all machined out of a lightweight aluminum that was available in the machine

shop. The parts can be seen

assemble and installed in the figure below.

Figure

17: Picture of the shifter mounted in the formula cockpit

The figure above shows the formula shifter assembled and mounted to the

side of the cockpit. The parts you

see are the only moving parts located in the cockpit.

The rest of the moving parts and wires will be located outside the

cockpit in a separate area in order to make sure that the driver does not

entangle themselves in the extra parts. The

shifter works exactly like a motorcycle shifter, to shift up a gear pull the

shifter toward the driver and to shift down a gear push the shifter away from

the driver.

Pedals:

All

of these parts were designed and manufactured by the group in order to fit the

formula car perfectly. The parts

are all machined out of a lightweight aluminum that was available in the machine

shop. The parts of the pedal can be

seen in the figure below.

Figure

18: A picture of a disassembled

pedal that will go on both of the cars

Figure

19: Picture of an assembled pedal

that will go on both of the cars

The figure above is a picture of a pedal that will go on both the formula

and baja cars. It is a standard pedal design that we are using for the

accelerator and the clutch of the formula and baja cars.

The brake pedal is essentially the same thing with a little added weight

to make the braking of the vehicle easier.

The main weight that is added to the pedal is in the top of the pedal to

make it more top heavy and the brake pedal easier to depress.

Baja

Frame:

The old Baja frame did not allow much room to work with inside the

cockpit. It did not give much room

to install all of the components necessary without sacrificing some things in

return. The old cockpit was too

short and narrow for the larger drivers as seen in the figure below.

The taller drivers knees would stick out of the side of the vehicle and

this is a major safety hazard in the case of an accident.

Figure:

A picture of a larger driver inside the old cockpit

The new frame is built out of long steel pipes.

The steel pipes had to be measured, cut, bent, and welded.

First, the long pipes had to be measured and cut to the correct length

before they could be bent. Then,

the pipes were marked where they needed to be bent and put in the pipe bender

that can be seen in the picture below and to the left.

The next step is to weld all of the bent pipes together to make the

frame.

Figure:

Pictures of bending and welding the Baja frame

The

new cockpit has increased hip room by allowing side impact members to go

straight forward rather than slant in. The

overall length of cockpit has been increased by 10”.

The best thing is that the overall frame dimension of the Baja car only

changes in:

–

Height:

- 1”

–

Length:

+ 1”

–

Width:

+ 1”

Figure:

A picture of the extra room in the new cockpit

As seen above, the new frame has much more room to work with than the old

frame. The new frame allows us to

put the pedals further away from the driver.

The new frame ensures that the taller drivers will not have to have their

knees sticking out of the side of the vehicle, which will make them much safer

in the case of an accident.