1.6 Concept Selection

Justification of Concept Selection Technique: House of Quality

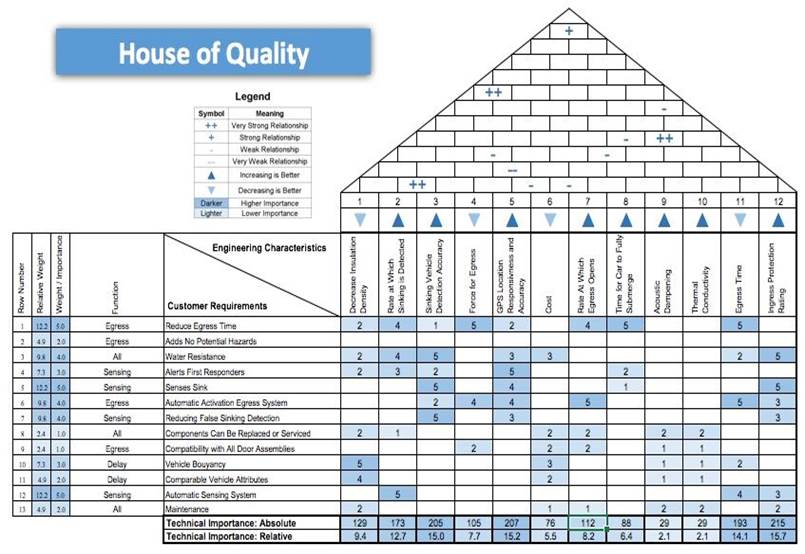

After identifying feasible design concepts and target metrics based off of our customer requirements, a House of Quality was created to better understand our customer. The House of Quality proved useful in finding the most important engineering characteristics based upon the importance of each customer requirement to our design. Also, the roof of the House of Quality outlined positive and negative correlations between our engineering characteristics to help in deciding which attributes of the design idea are most important to increase or decrease. After review of the House of Quality, an educated decision can be made on the most important functions of our sinking vehicle safety system. The customer requirements and importance were determined from our customer interview. The importance is weighted on a scale of 1-5 with 5 being the most important and used to determine the technical importance of each engineering characteristic. The engineering characteristics are weighted 1-5 based on how increasing or decreasing the engineering characteristic affects the customer requirement with 5 depicting a large correlation.

Figure 7: House of Quality

The technical importance of the engineering characteristic was used to evaluate which engineering technique was most valuable to the success of our sinking vehicle safety system. The technical importance is found by analyzing the engineering characteristic correlation with the customer requirement and the importance of the customer requirement. The top 5 most important engineering characteristics based on the relative technical importance were found to be: increasing water resistance measured in ingress protection rating, accuracy and responsiveness of GPS location services, increasing rate and accuracy of detecting a vehicle that is sinking, time for egress, and decreasing insulation density. Moving forward, these engineering characteristics must be focused on when deciding on the most effective design concept to increase safety in sinking vehicles.

Justification of Concept Selection Technique: Pugh Chart

After review of the House of Quality and determining the most important engineering characteristics, these evaluation characteristics were used in a Pugh matrix to evaluate each design concept against a datum. The datum was assumed to be a 2017 Toyota Corolla with standard options including Toyota SafetyConnect. This feature is used in emergency situations such as a sinking vehicle incident in hopes of increasing safety. A Pugh chart was created for each function of our system, sense, egress, and delay in order to determine the most promising design concept based upon our engineering characteristics from our House of Quality. The importance of each engineering characteristic is consistent with the weight of the customer requirement associated with it shown in the House of Quality. Each criteria was rated for the datum and design concepts on a scale of 0-2, with 0 representing a poor rating relative to the datum, 1 representing equivalence to the datum rating, and 2 representing exceeds customer requirements relative to the datum. After rating each criteria, the datum and design ideas are evaluated using the importance of the attribute and the rating given. Comparison with the datum score shows if the design concept will increase or decrease the sinking vehicle’s safety and allow a best design to be chosen.

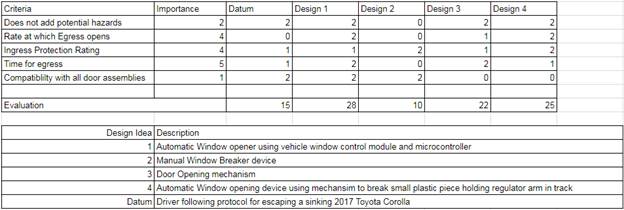

Justification of Concept Selection: Assisting in Egress

The evaluation criteria were found using the customer requirements from our customer interview and the technical importance determined from the House of Quality. The evaluation criteria and its importance are shown in the Pugh chart below in Figure 8. The time elapsed during egress is the most important criteria for this function and is weighted with a 5 for importance. By decreasing the time it takes for the distressed passengers to escape, more lives will be saved. The water resistance of the egress system, measured by ingress protection rating is also very important as the system must work will in wet conditions. The rate at which the egress route opens is essential as increasing this rate will prove to give the passengers more time to escape.

Figure 8: Egress Pugh Chart

Design concept 1, the automatic window opening system using an existing 2017 Toyota Corolla window control module and microcontroller design was selected as the best design concept after weighing each design against a datum in a Pugh Chart. The design concept was found to have an evaluation score of 28 which was much better than the datum score of 15. This design meets or exceeds all customer requirements from the House of Quality above when compared to the other design concepts.

Design concept 4 was very competitive as this design was rated at 25, only slightly lower than the winning design concept. Although design 4 met many of our customer needs it is not compatible with all door assemblies. Also, as the water pushes the window against the door it becomes harder for the window to fall by gravity itself; this causes a slower time for an egress because the route to escape becomes blocked which gives design 1 the edge over design 4. Design concept 3 was the only other design to reach a score greater than the datum but proved ineffective due to the door opening mechanism to perform worse in rate at which the egress route is opened. For the door to open, the pressure differential must reach equilibrium but this may prove to take too long to save the passengers. Also, we eliminated the automatic door opening mechanism as a potential concept because it not only contradicts our customer needs, but also it is more expensive than our budget will allow. Design concept 2, The manual window breaker device, was first to be eliminated and was scored very poorly due to the concept design not adhering to our customer need of not adding any potential hazards. Breaking the window would introduce the potential hazard of broken glass, it complicates the escape route causing for a slower opening egress time than other concepts further lengthening the time required for egress.

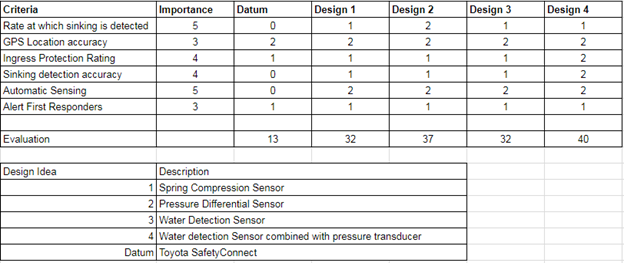

Justification of Concept Selection: Sensing

The sensing system using a pressure transducer incorporated with a water sensor design was selected after weighing each design against each other using a Pugh chart. After listing each design and assigning them values based upon how well they meet our customer needs we were able to determine which concept to consider. Upon creating the Pugh chart, the group originally had three designs: spring compression sensor system, pressure differential sensor system, and water detector sensor system. After conducting additional research, it was determined that it would be more effective and efficient to combine the pressure differential system (with the use of a pressure transducer) and water detection sensor system. This was concluded and calculated to be the best option due to the fact that both systems, individually, lack a customer need of reducing false sinking detection. The pressure differential sensing system lacks the ability to actually detect the first signs of water entry just as the water detection sensing system lacks the ability to accurately reduce or eliminate false positives for sensing if the vehicle is actually sinking or not. The calculations can be seen in the Pugh chart below in Figure 9.

Figure 9: Sensing Pugh Chart

The first concept design, spring compression sensor system, was eliminated due to the placement of the sensors. The sensors would be located on the springs of the suspension system of the car, which may take some time to decompress, forcing the group to have to account for this time delay and how that would affect the time of egress. These seconds could be the difference between being able to save the lives of the driver and passengers. The system would have to be able to sense when the car is in a state of suspension, send a signal to the design selected for egress as well as to first responders, and still allow enough time for egress. Accounting for the delay of sensing when the car is in a state of suspension, due to the time for spring decompression, the amount of time needed for egress would have to be increased. This would prove difficult if the selected method of delaying rate of sink could not meet the necessary time requirement due to standard materials, which still need to be comparable to the vehicle’s attributes, not being able to delay the rate of sink for x amount of time. Thus, this design was eliminated based on the delay for decompression of springs as well as not fully being able to meet all criteria, customer requirements, listed in the Pugh chart.

The second concept design, pressure differential sensor system, is kept as a close second feasible option in case the winning design proves to be infeasible. The group members decided that this would be the best option as a “Plan B” because the amount of water in the car could continually be updated as water entered the car, due to the transducer being able to measure the water pressure difference. The water pressure difference is equivalent to the difference in atmospheric pressure and water pressure at the depth of the sinking vehicle. Once the pressure difference reaches designated critical value, the pressure transducer would work with the sensing system and Toyota SafetyConnect to alert first responders on the emergency at hand as well as the GPS coordinates of the car. This system would also be one of the easier concept designs to waterproof due to the many variations of waterproof pressure transducers. The only issue with this design is that it will not be able to detect the first oncoming signs that water has entered the car. If the winning design concept proves to be infeasible, a solution will be constructed so that the pressure differential sensing system will be able to use a certain pressure to indicate that a certain amount of water has entered the car and is not quite a hindrance to the passengers at that current moment in time.

The third concept design, water detection sensing system, proved to be as effective as the first concept design in the sense that it, too, did not meet all the customer requirements. The water detector would only be able to do just that, detect water. A signal would be sent to the first responders alerting them that the car is sinking as well as working with the SafetyConnect already installed in the car to send the GPS location. Being able to reduce and eliminate false positives would also be semi-difficult due to heavy rains, opening and closing the door in these types of rains, and several other variables that would have to be accounted for. The main issue with this system is that the system would not be able to accurately measure how deep the car is in the water because the detector only detects water and sends a signal based on the water detection. This proves beneficial in the sense that it would be able to detect when water first enters the car and once it reaches a certain level, the water detector would warrant a reaction from the system. Although the water detection system has a certain level of water resistance, it’s not enough for the entire system to be reliant upon.

The winning concept design is design 4, the sensing system using a pressure transducer and water detector. The reason this design triumphed over all other designs is that it covers all bases, while meeting all the requirements of the customer. This design also scored the highest in the Pugh matrix and included the most engineering characteristics, specific to sensing, in the House of Quality. This system is not just using one sensor, it uses two, which increases the accuracy of the overall sensing system. Combining all the pros of the pressure differential system and the water detection sensing system and with the cons of each system being cancelled out by the combination of both, this systems proves to be the most effective and efficient out of all four concept designs. First, the water detector will be able to detect when water first enters the vehicle, which is what the pressure differential system lacks. However, the combination of the water detector and pressure transducer reduces/eliminates the possibility of receiving a false positive, which is the main concern with the water detection sensing system. It meets all the customer needs because the conjoined system reduces time needed for egress and it doesn’t add any potential hazards, due to the system simply being a sensing system and not interfering with the passengers. It also will not warrant a reaction from the system unless it is actually sinking and not signaling false positives. The system is water resistant, automatically sends a signal to activate the automatic egress system, the components can be easily serviced, relatively comparable to the vehicle attributes, and senses sinking, alerting First Responders when water is detected.

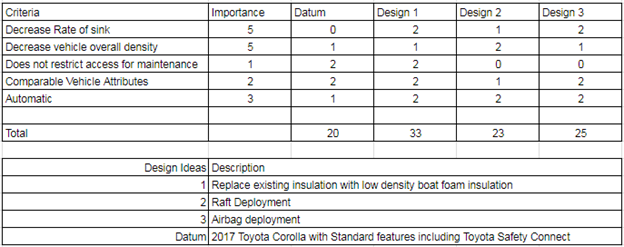

Justification of Concept Selection: Delay Sink

The evaluation criteria were found using the customer requirements from our customer interview and the technical importance determined from the House of Quality. The evaluation criteria and its importance are shown in the Pugh chart below. Decreasing the rate at which the vehicle sinks, and decreasing the overall vehicle density were found to be the most important criteria for delaying the sink function and is weighted with a 5 for importance. By decreasing the rate at which the vehicle sinks, more lives will be saved due to additional time before the vehicle submerges. Figure 10 below shows the Pugh chart used to evaluate the delay sink design concepts based upon our most important engineering characteristics.

Figure 10: Delay Sink Pugh Chart

Design concept 1, replacing existing insulation with low density boat foam, was selected as the best design concept after analyzing each design against a datum in the Pugh chart. The design concept was found to have an evaluation score of 33 which exceeded the datum score of 15. This design meets or exceeds all customer requirements from the House of Quality above when compared to the other design concepts.

Design concept 3 was most competitive with the winning design concept as this design was rated at 25, only slightly lower than the winning design 1 concept. Although design 3 met our customer needs it restricted access for maintenance and is costly. This results in less marketability and may not appeal to vehicle original equipment manufacturers as it could increase manufacturing costs extensively.

Similarly to design concept 3, design concept 2 proved ineffective due to not being feasible when cost and maintenance are taken in effect as well. Also interior vehicle attributes would change as a deflated raft and inflation system will affect the vehicle dampening and acoustics. This design seems unfeasible to pitch to an OEM in hopes to decrease the rate of sinking minimally for a large price. After analyzing the house of quality, it is evident that delaying the rate of sink in a sinking vehicle is the least important of our 3 main functions in improving safety in sinking vehicles.