1.5 Concept Generation

Function: Delaying sink

Description:

Decreasing

the rate at which the vehicle sinks will provide more time for egress for the

passengers in a sinking vehicle. The buoyancy force of this function will be

comprised of one system in place to increase the buoyancy of the vehicle and

increase the time the passengers have to escape. Four viable concepts were

generated during our ideation phase. Decreasing the rate at which the vehicle sinks is not required as part of the project scope but will prove very valuable

when giving distressed passengers a few more moments

time to escape.

Table

1: Delay sink concept generation

|

System |

Concept |

Metrics |

|

Vehicle

Insulation |

Replace

foam in vehicle with lower density foam |

Time (s) to sink a

specific depth, Acoustic (Hz), thermal

(k) properties, density (ρ) |

|

Vehicle Insulation |

Replace and add in

additional lower density foam to empty spaces in vehicle |

Time (s) to sink a

specific depth, Acoustic (Hz), thermal

(k) properties, density (ρ) |

|

Vehicle Insulation |

Vehicle

water ballast |

Time (s) to sink a

specific depth, Acoustic (Hz), thermal (k) properties, density (ρ) |

|

Vehicle Safety system |

Deploy flotation device |

Time (s) to sink a

specific depth, Time (s) to deploy

flotation device |

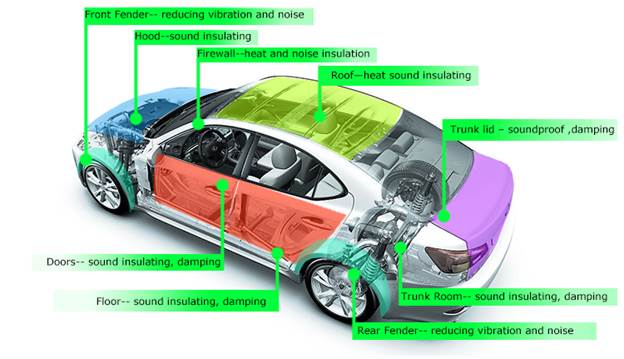

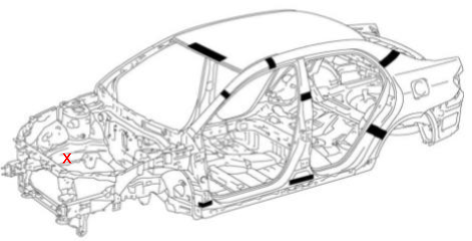

System: Vehicle Insulation

The insulation system is comprised of different

materials placed throughout the vehicle between the vehicle frame and interior

to provide ideal thermal and acoustic properties. Specifically, areas under the

hood, interior side, and floor panels utilize foam used to trap and reduce the

heat from the engine. The foam also acts as an acoustic damper to suppress

noise from the engine. These properties must be taken into account to ensure

our design concept does not take away from the vehicle’s original thermal and

acoustic properties.

Figure 1: Vehicle

Insulation system

Concept 1: Replace existing insulation

in vehicle with lower density material

Replacing the

existing material in the vehicle with low density foam will increase the

buoyancy force therefore allowing the vehicle to sink at a slower rate. The

standard insulation material is currently used throughout the vehicle and can

be replaced in key areas such as under the hood, front and rear fender,

interior floor, side panels, and trunk. Also the replacement material must be

comparable in acoustic and thermal properties to ensure the vehicle is not

hindered from our design concept. Several materials have been researched for

use in the vehicle.

Closed cell

urethane foam has been researched as a viable low density foam option. The foam

has a density of 2 lb/ft^3 which is much less dense

than water at 62.4 lb/ft^3. It has an R-value

of 7 per inch which is comparable to other types of insulation. The foam is

mixed and molded into a desired shape to fill voids for flotation and is relatively

inexpensive. However when urethane foam absorbs water, the buoyancy force

decreases significantly.

Expanding

epoxy foam was also researched as a viable option but is much more expensive

than urethane foam. Epoxy foam does operate better at higher strength and

temperatures and is more water resistant.

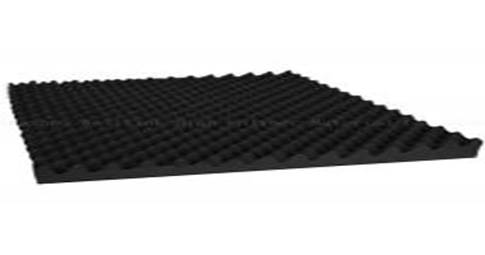

Low density

egg crate shape soundproofing foam is another option in areas that thermal

insulation is not a priority, such as the trunk or cabin. The egg crate shape

foam acts as a sponge to absorb sound as most of the material is comprised of

pockets of air. The pockets of air will prove to decrease the average density

of the vehicle allowing an increase in buoyancy.

Figure 2: Low density egg crate shaped foam

Concept

2: Replace existing and add additional lower density material in vehicle

This design concept is similar to concept 1 but includes adding

additional foam to areas occupied by only air between the vehicle’s frame and

side panels. However, adding in additional foam must not hinder the car in any

ways especially thermal and acoustic properties. Additional areas aside from under the vehicle hood, and interior panels

must be investigated to ensure it will provide more buoyancy without affecting

these qualities. Similar foams will be investigated for use as discussed in

concept 1.

Soundproofing

techniques provide examples of additional areas where low density sound

proofing foam could be applied to reduce the average density of the vehicle and

further sound proofing the vehicle comparable to standard options from the Toyota

corolla.

After

discussion during our staff meeting, it was brought to our team's attention

that all areas even if only occupied by air are designed with a specific

purpose such as acoustic dampening. By adding in foam to these areas, the

dampening in the vehicle may be thrown off and hinder the original vehicle

design. Extensive investigation must be done to ensure that any areas with

newly added foam do not hinder the vehicle’s properties.

Figure 3: Cabin Interior Insulation

Figure 3: Cabin Interior Insulation

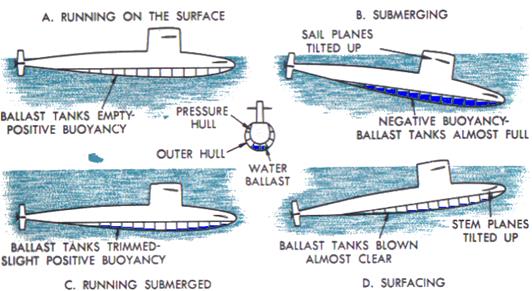

Concept

3: Vehicle air ballast tank

Marine

vehicles use water ballast tanks to increase stability and buoyancy. A ballast tank is a compartment within a

floating structure that holds water, which is used as ballast to provide stability

for a vessel. This

component of marine vehicles could be applied to our project but as an air

ballast tank. By sealing areas in the vehicle so water cannot occupy those

areas, the trapped air will increase the force of buoyancy and decrease the rate

of the sink. Areas that could be potentially be sealed are pockets between the

frame and interior. Other areas, such as the exhaust system, could provide more

volume for the air to be used as a ballast but could prove to be unsafe for the

vehicle if the exhaust system is accidentally sealed during normal operation.

Figure 4: Water Ballast principles

System: Vehicle safety systems

The vehicle

safety systems include components such as seat belts and airbags. Airbags could

prove useful in creating buoyancy in a sinking vehicle and should be

investigated. Although no additional safety hazards, such as a

instantly deployed airbag, should be added to the system in order to abide to

our customer restraints. By adjusting the way in which the airbags are activated,

they could prove useful in delaying the rate at which the vehicle sinks.

Concept 4: Deploy flotation device

Several

components already installed in the vehicle could be used as a flotation device

to increase buoyancy of the vehicle and delay the sink. Airbags could be

inflated slowly to increase buoyancy of the vehicle by trapping pockets of low

density air but not add any potential safety hazards that usually accompany a airbag deployed at full

velocity. The airbags would continue to stay inflated in this case instead of

slowly deflating immediately after a car accident. However, each deployed air

bag would have to be replaced and could prove very costly to the operator of

the vehicle.

In addition

to the airbags, more buoyancy can be achieved by putting an inflatable

flotation device similar to an airbag in the underneath the frame of the car.

Upon the vehicle sinking, it would be deployed and inflated to increase the

buoyancy of the vehicle. This would be necessary if the buoyancy force from deploying

the airbags was not great enough to make a real impact in delaying the sink.

Function:

Sensing sinking vehicle

Description:

Sensing the vehicle condition can provide the

passengers with appropriate assistance especially in life threatening situations.

This function will be comprised of one system in place to provide the

passengers with contact with emergency first responders and signal a means to

egress the vehicle. After refining initial concepts, three viable concepts were

generated for this function. The vehicle electrical system is required to

validate our design as it will be integrated with our design concepts in order

to achieve the top priority of the project scope, saving lives in a sinking

vehicle scenario.

Table

2: Sensing sinking vehicle concept generation

|

System |

Concept |

Metrics |

|

Vehicle Electrical System |

Install a pressure

transducer underneath the body of the vehicle |

Pressure (kPa) |

|

Vehicle Electrical System |

Install a force

transducer along the vehicle suspension springs |

Force (kN) |

|

Vehicle Electrical System |

Utilize existing GPS

location device on vehicle |

Change in

elevation (m) |

System: Vehicle electrical system

Most

vehicle’s electrical systems made after fall 2009 come equipped with a variety

of sensors to help aid the driver. Such sensors include GPS location and force

transducers. The GPS location sensor is used to provide vehicle navigation.

Force transducers detect large forces which are indicative of a vehicle

accident. Toyota’s Safety Connect program utilizes the GPS location and force

transducer data to send emergency first responders to the location of the

vehicle in the event of an accident. While most new vehicles come equipped with

a variety of sensors, more can be done to detect if a large body of water is involved

during an accident.

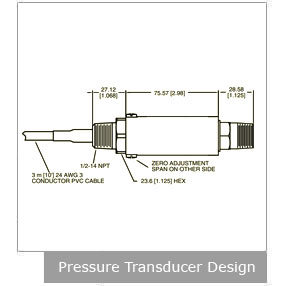

Concept

1: Installing a pressure transducer

The pressure transducer works by converting

pressure into an analog electrical signal. This is achieved by physically

deforming strain gages that are bonded into the diaphragm of the pressure transducer

that are wired into a Wheatstone Bridge configuration.

The pressure being applied to the pressure transducer produces a deflection of

the diaphragm. The deflection or strain will produce a proportional electrical

resistance to the applied pressure. Figure 1 below shows a schematic drawing of

a standard pressure transducer.

Figure 5:

Pressure transducer design from Omega.com

The electrical signal can then be used to alert

first responders that the vehicle is potentially sinking in a large body of

water. The signal could also be used as a means to begin the automatic window

drop function discussed in the assisting in egress section. The signal would be

sent to an intermediate computer that would also be connected to the window

position switch. The window would drop as normal if a signal is received that

the car is underwater a signal that the car is in water.

Installing the pressure transducer along the undercarriage is the

preferred location for this concept since most vehicles enter water in the

upright position. Figure 6 below shows the preferred location for the pressure

transducer. The concept will focus on making a meaningful impact on the number

of vehicle deaths involving water. Vehicles entering water in other

orientations will be beyond the scope of the current project but may be

addressed during future projects.

Figure 6:

Body outline of 2009 Toyota Corolla from slideshare.net indicating location of

pressure transducer.

Concept 2: Installing a force

transducer on the suspension springs

This force transducer would work with the suspension system

used in the vehicle. When a vehicle’s weight is equally distributed between

four tires on the ground and their suspensions, the springs are compressed to a

standard point. However if the same vehicle is sinking, the amount of force on

the tires from the water would be significantly less and would result in a

spring that was elongated. The force transducer would be able to detect this

difference in length by monitoring the amount of force the spring was enduring.

When the force on all four tires’ springs dipped below a calculated point and

stayed there for a given amount of time, it would be able to determine if the

vehicle is sinking.

Concept 3: Utilize

existing GPS technology

Global Positioning System (GPS) technology is

steadily advancing, particularly in the automotive industry. Toyota launched

their Safety Connect system in 2009 which has four major functions, all of

which include the use of GPS technology: Automatic Collision Notification,

Emergency Assistance Button, Roadside Assistance, and Stolen Vehicle Locator.

To make these efforts possible, GPS systems must

depend on reliable networks which include ground stations, satellites, and

receivers. There are over 30 navigation satellites hovering in space and the

ground stations use radar to reassure the overall system that the satellites

are in their “assigned” spots in space. Receivers, particularly built in

receivers in an automobile, listen for signals from the satellites. Once four

or more distances are collected by the receivers from the satellites, the

receivers then send a signal to first responders or the GUI (Graphical User

Interface i.e. built-in touchscreens on consoles) to display the location of

the car, navigate accordingly, or assist in /perform the task at hand.

By “piggybacking” off of the already existing

GPS technology and wiring, a pressure sensor can be used in conjunction with

this GPS technology in its own module to effectively and efficiently send a signal

to the Response Center so that First Responders can be alerted in a timely

manner. The latitude and longitude of a vehicle’s location is included among

the numerous data that is collected and used by Toyota. If the coordinates of

the vehicle could bypass the Response Center and go directly to First

Responders when the pressure difference of the water is first detected, this

would help reduce the response time of emergency personnel.

Concept 4: Combining Pressure Transducer and Water Detection

System

The pressure differential system uses a pressure transducer

to measure the difference in the atmospheric and water pressure which allows

the group members to set a critical pressure point signaling that the car is

sinking and not experiencing other case scenarios (i.e. heavy rains or going

through a car wash). Once the water is detected, a signal will be sent to the

egress system, in a timely manner, and passengers can begin their escape,

allowing time for all 3 passengers to get out of the car. The conjunction of

water detection and pressure differential systems can also send a more accurate

GPS location to First Responders, including depth by using the pressure

transducer’s pressure difference, in a timely manner, with the water detection

and pressure transducer working together to ensure the car is sinking as soon

as the water is detected.

Function:

Assisting in egress

Description:

Assisting the

passenger in egress is essential to increasing the survival rate in sinking

vehicle accidents. This function will focus on modifying the various exits

throughout the vehicle as well as creating a new means of egress that will make

it easier for passengers to escape while sinking. Three feasible concepts were

generated during our ideation phase. Considering that many people become

trapped inside the vehicle while it is sinking, a system designed to assist all

passengers in egress is required for our project scope to increase the chance

of saving lives.

Table

3: Assisting in egress concept generation

|

System |

Concept |

Metrics |

|

Vehicle Window Regulator

system |

Manual window dropper |

Time (s) for egress, Time

(s) to fully open window |

|

Vehicle Window Regulator

system |

Automatic window dropper |

Time (s) for egress, Time

(s) to fully open window |

|

Vehicle electrical system |

Underwater door opening

mechanism |

Time (s) for egress, Time

(s) to fully open door, Force (kN) to open door

while vehicle is submerged |

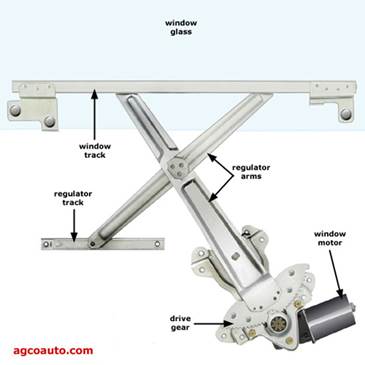

System: Automatic Window Regulator

System

Most cars

manufactured in the past 10 years are equip with power window regulators used

to open and close the window using a button. The automatic window regulator

system is used throughout the vehicle and allows the passengers to open or

close the windows with a push of the button as opposed to physically cranking

the window. Our concepts would allow for the window to drop to allow for the

passengers’ egress but would not affect the window regulator system’s current

function.

The first

design concept question was how the passenger should exit. One option was for

the system to break the windows. However, one of the project constraints was to

not add any potential hazards such as broken glass to the situation. Thus,

focusing on the window regulating system will provide an opportunity to open a

window for the passenger quickly and safely.

Figure 7: Vehicle Window Regulator system

Concept 1: Manual Window Dropper

The manual

window dropper will function using a lever near the bottom corner of the driver

side window that will drop the driver side front window. This design concept

would not be a part of the vehicle’s system that included the sensor as it

relies on the passenger to engage. This could be useful in the event that the

electrical system fails due to impact or water damage but the system would rely

on a distressed vehicle operator to have to activate the lever quickly in order

to survive. Once the manual window dropper is activated a signal would be sent

to first responders similar to Toyota's safety connect.

Precautions

must be taken to ensure the window will still drop even if the water level has

risen to the height of the window. As the water level increases in height on

the window pressure forces will continue to rise, risking failure in the

dropper mechanism and failing to drop the window for the sinking passengers.

Concept 2: Automatic Window Opener

This concept

would work with the window regulator system and would automatically drop the

window. The window dropper would be integrated with the sensing system that

would be able to detect the vehicle sinking. This system would include the

sensor as previously mentioned that would signal the window dropper to activate

automatically in the event that the vehicle is sinking..

By automatically dropping the window, the passenger would have a means to

escape the vehicle without having any direct interaction with the window

itself.

During the

first minute of the sink, the passengers in the vehicle have the highest chance

of survival as the water level will not at the top of the window. Once the

water level is near the top of the window, pressure forces are exerted against

the window and could prevent it from being dropped. To ensure this is not the

case, the automatic window dropper must drop the window at full velocity within

0.5 seconds of the sensor sensing that the vehicle is sinking.

Special

precautions must be taken to ensure the automatic window dropper does not

accidentally activate due to a splash of water or hitting a speed bump.

Concept 3: Underwater Door Opening

mechanism

An underwater

door opener concept would be integrated into the electrical systems of the

vehicle so that enough power could be produced to force open the door while the

vehicle is sinking. This mechanism would assist the passengers in opening the

door despite the growing force of the water pressure on the outside of the door

as the vehicle is sinking. The opener would be placed within the door frame and

as the sensors detect the sink of the vehicle, this mechanism would begin to

expand. As it expands, the door would open and create a means of escape.

It becomes

increasingly more difficult for the door of a car to open as a car sinks. This

means that the car door must be opened almost instantly upon impact with the

water. The automatic door opening system must be activated the instant that the

sensor network senses that the car is in water, and it must open the door in

less than 4 seconds to ensure that the passengers can escape. The door opener

must work very quickly because if the door is open it allows much more water to

enter the cabin of the vehicle than if only a window is open, causing the

passengers to have less time to escape from the vehicle before it fills

completely with water.

Precautions

must be taken to ensure that the automatic door opener can withstand the force

of water outside of the vehicle even after the water reaches the top of the

door. As previously stated, as the water level rises the amount of force needed

to open the car door also rises.

Figure 6: Installed Window Regulator

Figure 6: Installed Window Regulator