NASA has invested heavily in the exploration of Martian

surfaces. This has created a drive for a more efficient means of operation.

Achieving this goal requires higher fuel efficiencies and a lower rover mass.

Since a large percentage of a spacecraft’s mass comes from fuel, reducing fuel

mass reduces the total rover mass and allows the rover to operate more

efficiently. Other large contributors to the mass of mobile rovers are charging

and energy storage systems. Large solar arrays and radioisotope power

generation systems can be heavy. A mission that includes a stationary charging

base trades rover mobility for efficiency. One drawback of this strategy is

that the rovers must stay within a predetermined radius of their charging

station, but gain efficiency by reducing the amount of onboard power storage.

Moving the power generation, communication, and sample analysis systems to the

stationary lander base significantly reduces rover mass. NASA has an existing

Martian lander with several technologies on the deck. The lander will

remain stationary and generate power via a bank of hydrogen fuel cells.

This power must be transferred to excavators on the surface to charge

batteries aboard excavators.

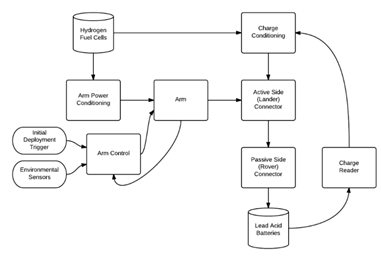

Our team

is responsible for transferring power from hydrogen fuel cells (HFCs) on board a

stationary lander deck to lead-acid batteries (PbACs) on board mobile rovers.

This system is manifested as a robotic arm with attached umbilical connections

which is capable of transferring power from the HFCs to the PbACs.

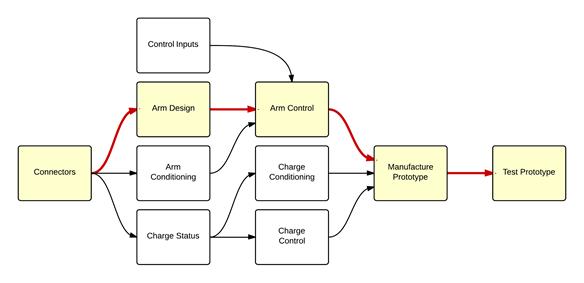

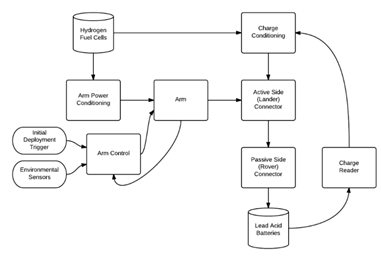

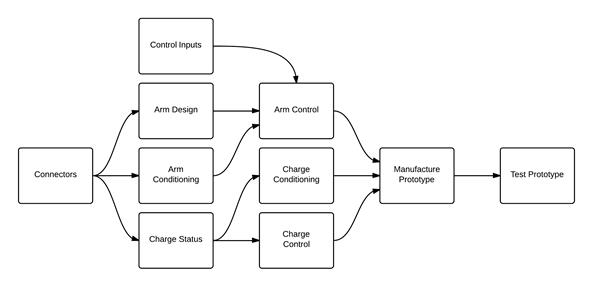

A top

level functional analysis diagram of our system can be seen in figure 1. The

HFCs and PbACs are provided by NASA and may not be modified by our team. The

team will be designing, prototyping, and testing the remaining components of

the system.

The team

has identified several subsystems that will need to be designed in order to

complete this task. The focal point of this project is a robotic arm. The arm

will be aware of rover position, make a connection to the rover, and charge the

rover to 100% capacity while providing feedback on charge status. The three

main subsystems for this project are the robotic arm itself, the arm control,

and charging. These primary subsystems may be further divided into smaller

subsystems.

The primary objective for the project is to recharge

batteries onboard extraterrestrial excavators located on the Martian surface.

The recharging station on the lander will function for the duration of the

mission, making the teams overall objective to establish a connection using an

umbilical arm from the HFC to the PbAC.

The finished prototype is to be completed no later than the

end of the academic year. This dictates that the prototype must meet all of the

design and performance specifications required by NASA in order to satisfy the

mission objective. To accomplish this, the project must be divided into major

and minor subsystems, which are to be analyzed and tested isolated from the

remainder of the system.

The tentative budget for the project is currently set at

$2,000, but is subject to fluctuation based upon government operational status

at the time the grant is issued for the project. Options to apply for an

additional grant are also available for the team if additional funds are

needed. The team must design around this budget, and must take into account

certain parameters of cost in materials selection, testing, and design.

NASA has requested unique deliverables from the team at

specific times during the course of the project. A deliverable will be

submitted to NASA upon completion of certain milestones during the year. Progress

milestones will be submitted to NASA upon completion of directed tasks. These

tasks correspond to approximately 30%, 60%, and 90% completion. These

milestones are to be submitted at the team’s discretion.

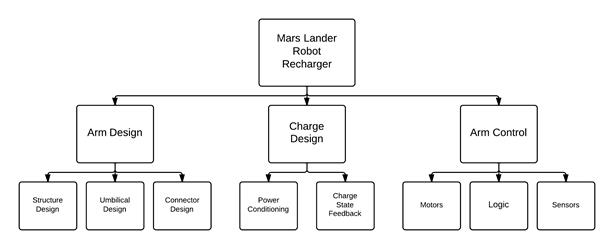

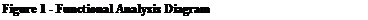

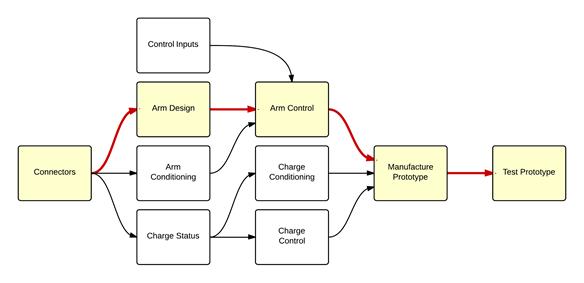

The project is divided into three major subsystems and eight

minor subsystems. These subsystems can be seen in figure 2.

Figure 2 - Subsystem Diagram

The project is divided into three major subsystems. These

subsystems are the Arm Design, Arm Control, and Charging. Within each

subsystem, there are minor subsystems. The minor subsystems within the Arm

Design subsystem include the umbilical design, structure design, and connector

design. The minor subsystems within the Arm Control subsystem are the sensors,

motor, and logic. The minor subsystems within the Charging subsystem are power

conditioning and charge state feedback.

Design decisions will be made using the following decision

matrix. Relevant criteria may be added as needed and not all criteria will be

used in every decision; however, most decisions will be made using matrix as

follows and its associated weights.

|

Criteria

|

Weighting

|

Concept #1

|

Concept #2

|

Concept #3

|

|

Mass

|

.18

|

|

|

|

|

Reliability/Redundancy

|

.18

|

|

|

|

|

Volume

|

.14

|

|

|

|

|

Robustness

|

.14

|

|

|

|

|

Cost to NASA

|

.11

|

|

|

|

|

Simplicity

|

.07

|

|

|

|

|

Efficiency

|

.18

|

|

|

|

There are many components of the system which we will be designing.

These components will be subjected to a variety of conditions in transport to,

landing on, and remaining on the Martian surface. The components will need to

be reliable in both terrestrial testing and extraterrestrial use.

The forces exerted on a structural member, such as the

desired umbilical arm depend primarily on the acceleration due to gravity.

Whatever design is decided upon must be able to function properly in the

Martian atmosphere as well as withstand the forces exerted during launch (3g on

manned missions and can be higher on unmanned missions). Because the Martian

gravitational acceleration is 37.8% that of earth, the umbilical arm will most

likely be able to withstand forces acting on it if it can survive exiting earth

orbit. Therefore, the majority of focus in designing the arm structure to

withstand forces will be on proper storage and transport.

Pressure on the Martian surface is 600Pa (about 0.6% that of

earth). The atmosphere is about 95% CO2. Operation of any components

using air as a dielectric, such as some capacitors, will need to be verified

under these conditions. Unless the components used rely on air as a dielectric,

the pressure and atmospheric composition will not have a major impact on any

design decisions.

The largest atmospheric condition which our team has to take

into consideration is the frequency of dust storms. The winds on Mars can reach

speeds upwards of 300mph, which can stir up the dust on the surface. Martian

dust is very fine and very erosive. Any components exposed to the atmosphere on

Mars will need to be capable of withstanding frequent battering by dust

particles travelling at upwards of 300mph.

The transfer of power which is to be performed is a transfer

from HFCs to PbACs. The HFCs are capable of producing between 24V and 32V. This

power will be utilized to charge the rover and to power the arm structure. The

overall efficiency of the power transfer is to be at least 75% efficient, with

a target efficiency of over 90%. Since this efficiency decreases with all power

being used by the arm, there is significant difficulty in designing a system

which can meet this criterion.

Our design must be lightweight in order to be used on the

mission. The arm and all components which are attached to the lander deck must

have a combined mass of under 4kg, while the components attached to the rover

body must have a combined mass of under 2kg, with a target mass of under 1kg.

This adds significant difficulty in design, as the parts must be as cheap as

possible, while still withstanding all necessary forces, convert power

appropriately, and be light enough to be practical on the Martian surface.

Our design must also be compact in order to be used on the

mission. The passive (rover) side of the connection must be capable of being

accessible without interfering with the mission of the rover. The active

(lander) side of the connection must be fully contained within the protective

shroud provided by NASA in transport to the Martian surface.

The project can be divided into three primary subsystems.

These are the arm design, charge design, and arm control subsystems. These can

be further divided into secondary, tertiary, and at times, quaternary

subsystems. The work breakdown structure can be seen below.

1

Mars Lander Robot Recharger

1.1 Arm

1.1.1

Umbilical

1.1.1.1

Content

1.1.1.2

Material Selection

1.1.1.3

Location

1.1.2

Structure

1.1.2.1

Geometry

1.1.2.1.1

Movement at endpoint

1.1.2.1.2

Force Analysis

1.1.2.1.2.1

Static Forces

1.1.2.1.2.1.1

Force and Moment

1.1.2.1.2.1.2

Stress and Strain

1.1.2.1.2.2

Dynamic Forces

1.1.2.1.2.2.1

Joints

1.1.2.1.2.2.2

Linkages

1.1.2.1.3

Computer Aided Design (CAD)

1.1.2.2

Material Selection

1.1.3

Connector

1.1.3.1

Geometry

1.1.3.2

Computer Aided Design (CAD)

1.1.3.3

Material Selection

1.1.4

Manufacture

1.1.5

Testing

1.2 Charging

1.2.1

Conditioning

1.2.1.1

Voltage Regulation

1.2.1.2

Testing/Debugging

1.2.1.3

Ripple Dampening

1.2.2

Charge State

1.3 Arm

Control

1.3.1

Initial Deployment Trigger

1.3.2

Sensor Input

1.3.3

Position Reading

1.3.4

Power Input

1.3.4.1

Conditioning

1.3.4.2

Storage

1.3.5

Motor Control

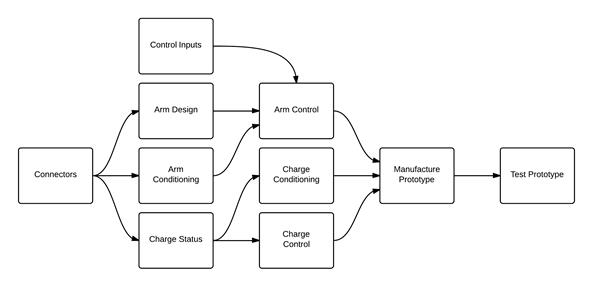

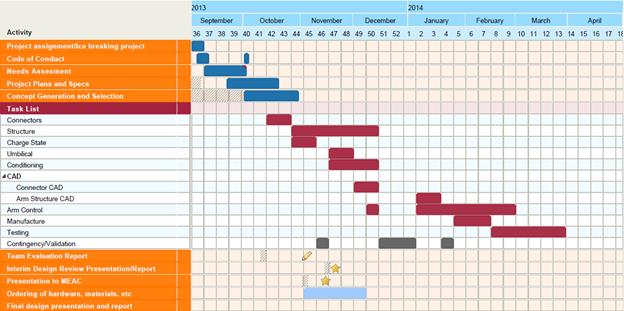

Each task in our project is dependent on each of the other

tasks. There is a certain workflow which must be followed in order that certain

design decisions may be made which have an impact on each of the later design

decisions. The task dependencies can be seen clearly in figure 3.

Figure 3 - Task Dependencies

The critical path is the path which is shaded in figure 4

below. This path will take the longest to finish and has many subparts which

will take a significant amount of time, as can be seen in section 6.1 of this

report.

Figure 4 - Critical Path

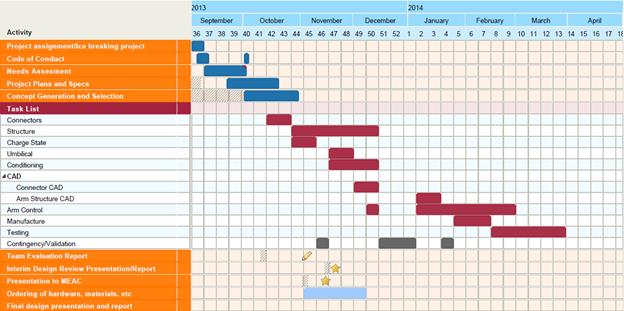

Figure 5 - Gantt Chart – Entire Team

The team will be working on

assigned tasks at the time stated in the Gantt Chart present in Appendix A. The

tasks will be completed in the order listed on the figure 5 in section 6.4 of

this report. All team members will collaborate in weekly team meetings and all

deliverables will be written collectively by the team, with the members

contributing data based on area of responsibility.

The current allocated budget

for the project is $2,000.00. The team is currently working on a budget

proposal which will determine if this $2,000.00 is sufficient to complete the

project or if any additional funds may need to be allocated for the successful

completion of this project.

Each of the specifications in this report were obtained either

through contact with Ivan Townsend, our QinetiQ point of contact or our own

research.

8.1 Lander and Rover Geometry

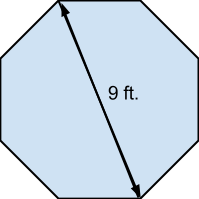

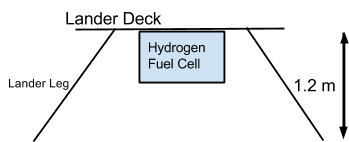

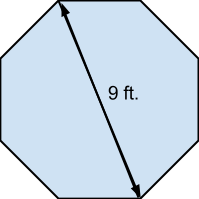

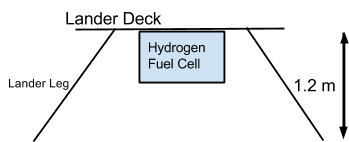

The lander deck shape is an octagon with a 9-foot distance

point to point and stands 1.2 meters (3.9 feet) above the Martian surface as

shown in Figure 6.

Figure 6a - Top View of Lander Deck

Figure 6b – Side View of Lander Deck

A hydrogen fuel cell is located in the belly of the lander

and provides electrical power for the lander systems and rover recharging

system. During space transit, the lander is stored inside a 3 meter diameter

shroud which surrounds and protects the lander. The arm is to be stowed in

transit to the Martian surface and deployed upon landing.

The arm which we are to design will deliver power to

excavators, which are approximately shin height (about 1 to 2 feet).

8.2 Lander and Rover Electrical Power Parameters

The lander is equipped with HFCs, capable of delivering an

output voltage between 24 and 32V. The PbaCs will start at approximately 50%

charge and will be required to be charged to 100% capacity in less than 8

hours. The minimum efficiency of this process is limited to 75% with a target

efficiency of above 90%.

8.3 Lander and Rover Connection Mass

The mass of the umbilical arm is restricted to be less than

4 kilograms. This includes the umbilical itself and any motors, motor drivers,

or structural mounts. The mass of the passive side (rover connection) is

restricted to be less than 2 kilograms with less than 1 kilogram preferred.

[1] http://www1.eere.energy.gov/hydrogenandfuelcells/fuelcells/fc_types.html

[2] http://www.afcenergy.com/technology/advantages_of_alkali_fuel_cells.aspx

[3] http://www1.eere.energy.gov/hydrogenandfuelcells/fuelcells/pdfs/fc_comparison_chart.pdf

[4] http://en.wikipedia.org/wiki/Atmosphere_of_Mars

[5] http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=1554624&tag=1

[6] http://www.jameco.com/Jameco/Products/ProdDS/178597.pdf

[7] http://www.space.com/16907-what-is-the-temperature-of-mars.html

[8] http://www.nasa.gov/audience/foreducators/topnav/materials/listbytype/What_Is_the_

Temperature.html

[9] http://quest.nasa.gov/aero/planetary/mars.html

[10] http://www.jpl.nasa.gov/news/press_kits/MSLLaunch.pdf