Fuel injection System

Nozzle Selection

Spray Nozzles

A nozzle is a

mechanical device that is designed to control fluid flow characteristics as

fluid, either liquid or gas, exits from an enclosed chamber into a chosen

medium. Nozzles are relatively simple in

design, usually a pipe or tube that varies in its cross-sectional area from one

end to another. Nozzles are used to

control different characteristics of fluid flow such as rate of flow,

direction, speed, mass, etc. Nozzles

also have the ability to control exit droplet size and fluid spray pattern,

which are the pertinent characteristics in this project.

Nozzle Selection

The following

characteristics are considered when selecting a nozzle: spray pattern,

capacity, spray angle, and droplet size. Spray pattern is dependent on the

function of the nozzle for its specific application. For the fuel jet injection

system a uniformly distributed spray pattern with a possible Gaussian

distribution is needed. Moreover, a relatively wide range of droplet sizes,

ranging from 500µm to 5000µm, need to be generated. Full cone spray nozzles

with different capacities (12-0.3 gpm) under different pressures (10-100psi)

can produce droplet sizes in the desired range.

Below

a tabulated summary is provided that contains different fluid properties and

nozzle characteristics and their effect on one another:

For

example; If there is an increase in the viscosity of the fluid

the associated "Nozzle Characteristic" is affected as indicated

by the indicated amount....

|

Nozzle

Characteristics

|

Increase in

Operating Pressure

|

Increase in

Specific Gravity

|

Increase in

Viscosity

|

Increase in

Fluid Temperature

|

Increase in

Surface Tension

|

|

Pattern Quality

|

Improves

|

Negligible

|

Deteriorates

|

Improves

|

Negligible

|

|

Drop Size

|

Decreases

|

Negligible

|

Increases

|

Decreases

|

Increases

|

|

Spray Angle

|

Increases then

decreases

|

Negligible

|

Decreases

|

Increases

|

Decreases

|

|

Capacity

|

Increases

|

Decreases

|

Full cone

increases

|

Depends on

fluid sprayed

and nozzle used

|

No effect

|

|

Impact

|

Increases

|

Negligible

|

Decreases

|

Increases

|

Negligible

|

|

Velocity

|

Increases

|

Decreases

|

Decreases

|

Increases

|

Negligible

|

|

Wear

|

Increases

|

Negligible

|

Decreases

|

Depends on

fluid sprayed

and nozzle used

|

No effect

|

Table 1: (Spraying Systems Co., [1])

There are many

terminologies used to describe the drop sizes within a spray; three of the most

commonly used terminologies are:

- Volume Median Diameter (VMD) also expressed as Dv0.5

and Mass Median Diameter (MMD)

Drop size is

expressed in terms of the volume of liquid sprayed, and when measured in terms

of volume is a value with 50% of total volume of liquid sprayed contains drops

with diameters larger than median value and 50% with smaller diameters.

- Sauter Mean Diameter (SMD) also shown as D32

Fineness of spray

is expressed in terms of surface area produced by the spray. SMD is the

diameter of a drop with the same volume-to-surface area ratio as the total

volume of all the drops to the total surface area of all the drops

- Number Median Diameter (NMD) or DNo. 5

Drop size is

stated as the number of drops in the spray. So, 50% of the drops by count or

number are smaller than the median diameter and 50% are larger than the median

diameter.

Volume Median

Diameter or VMD is the most popular known expression used to represent drop

size distribution in most nozzles.

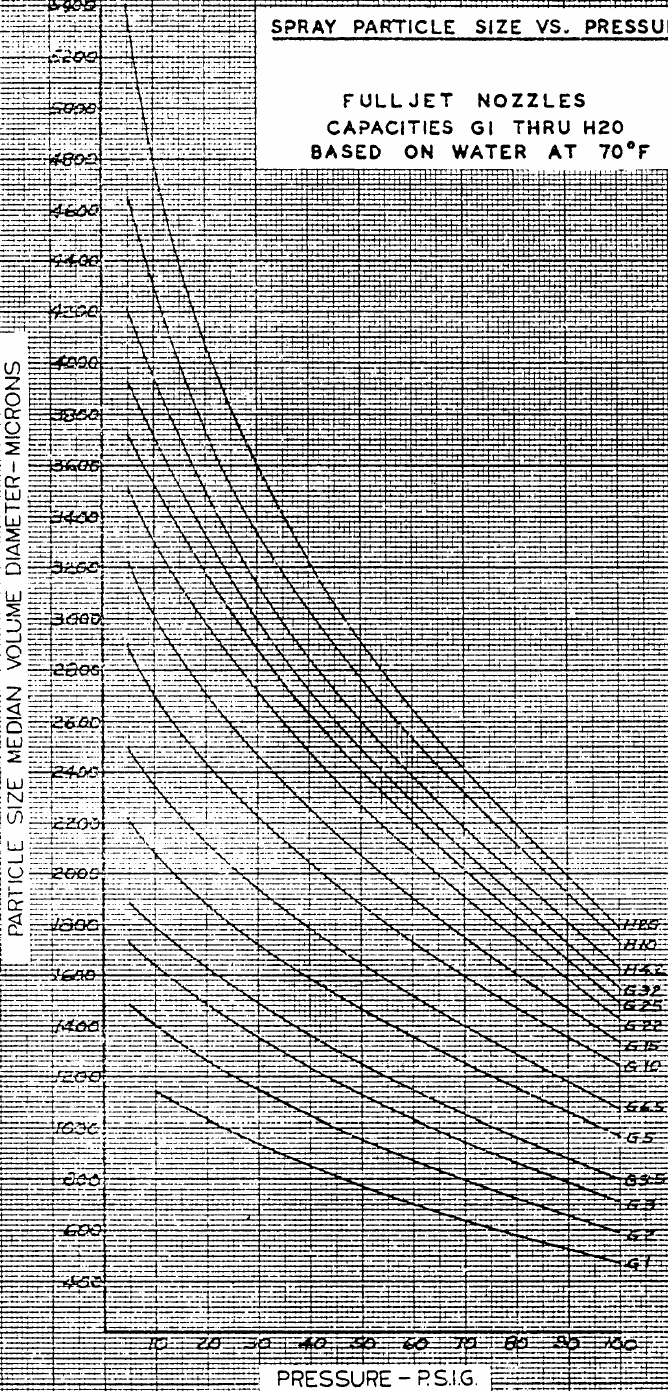

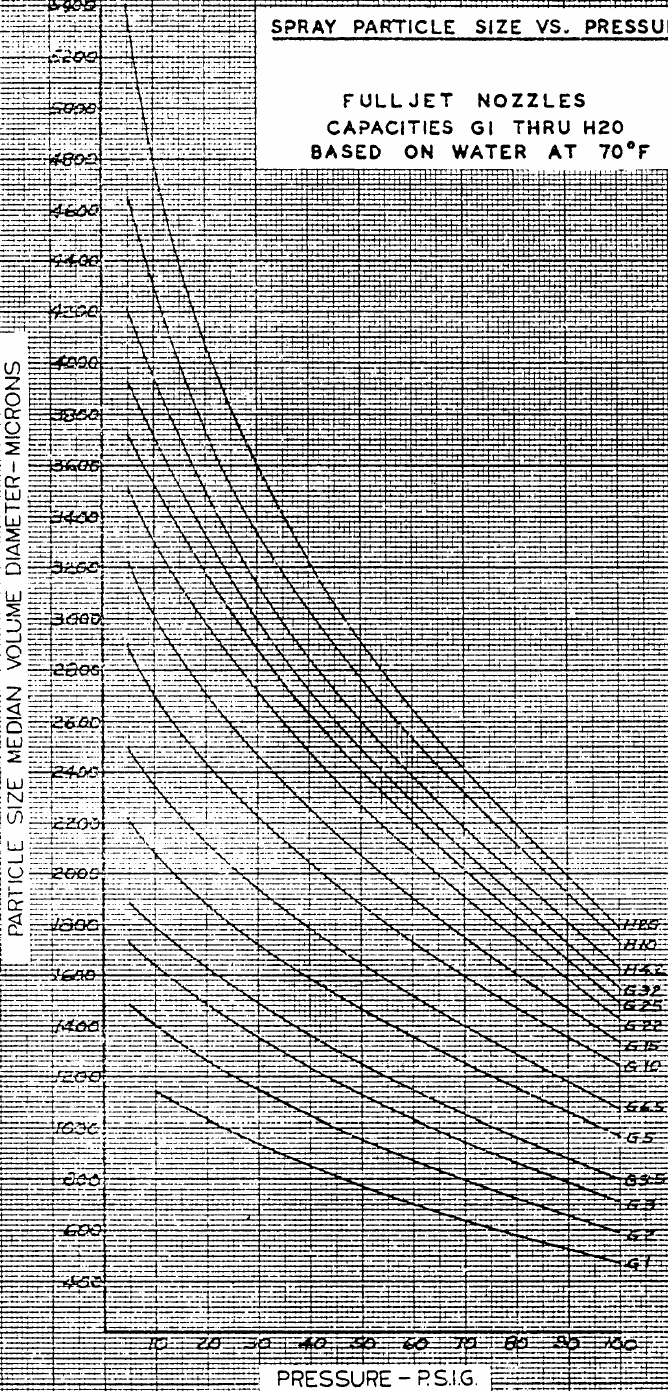

Final selection of the nozzle is

done by examining a graph provided by the manufacturer of the nozzle that gives

spray particle size in VMD versus pressure for standard full cone nozzles. The

graph is done for many nozzles with different capacities. It is very important

to mention that these tests were done for water and the particle size provided

is for water at room temperature. The graph is only used to aid us through

selecting the correct nozzle, but is in no case the final nozzle

characterization. The actual characterization of the nozzle will be done by us.

"Nozzle Selection, graph spray particle

versus pressure (Spraying Systems Co,[2])"

The actual nozzles

selected from Spraying Systems Company are the following:

Table 2- nozzle selection

|

Order number

|

Nozzle type

|

Capacity size

|

Material

|

Inlet Connection

|

Thread type

|

(VMD of water)

|

Pressure range for

VMD

|

|

1/8G-316SS1

|

G

|

1

|

316 Stainless steel

|

1/8”

|

Female NPT

|

500-1000µm

|

120-10psi

|

|

1/8G-316SS3.5

|

G

|

3.5

|

316 Stainless steel

|

1/8”

|

Female NPT

|

1000-1700 µm

|

90-

10psi

|

|

3/8G-316SS15

|

G

|

15

|

316 Stainless steel

|

3/8”

|

Female NPT

|

1500-3000µm

|

100-10psi

|

|

2-1/2H-SS25

|

H

|

25

|

316 Stainless steel

|

2-1/2”

|

Female NPT

|

2000-5000 µm

|

90-

5psi

|

REFERENCES

[1] Nozzle selection, table 1:

Spraying Systems Co., Engineers

Guide to Spray Technology, Page 8, year 2000

[2] Nozzle Selection, graph spray particle

versus pressure

Spraying Systems Co., DWG. No.

11825-8 ,Bellwood ILL, Sept. 27, 1966

|