This section includes a summary of the final design as well as pictures of each

component and diagrams that will illustrate how the system works.

Subassembly Components

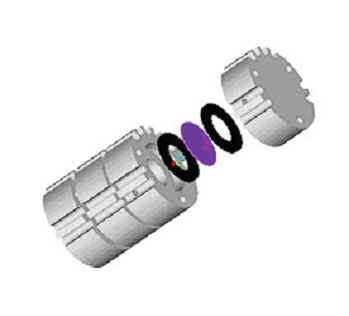

The figures below show CAD images of the individual components of the

subassembly as well as an exploded view of the subassembly including the fuel

cell and gaskets. Each subassembly component will be machined out of alumina

silicate purchased from Cotronics, Inc.

Each component of the subassembly includes a set of grooves along the outer

perimeter to accommodate the gas inlet and outlet tubes. Each compartment is

sealed from its neighbor by the combination of the fuel cell and the vermiculite

gasket on either side as seen below.

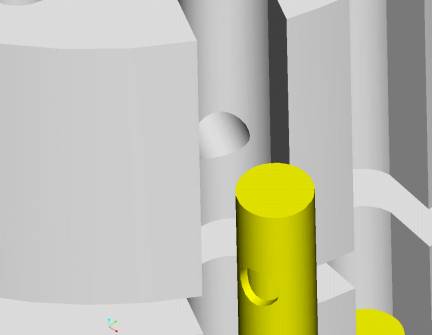

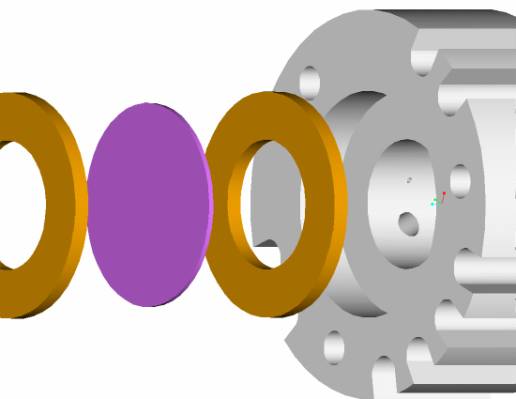

The figures below show an enlarged view of the connection between the gas

inlet tubing and the subassembly as well as an exploded view of how the gaskets

interact with the fuel cell and

subassembly.

Connection between gas tubing and subassembly

Interaction

between gaskets, fuel cell, and subassembly component

Gas Flow

The gas flow in our system has been simplified from the original idea of

perpendicular flow. This new design has the gas flows entering and exiting along

the main axis of the subassembly. A diagram of the gas flow in an individual

component is shown below.

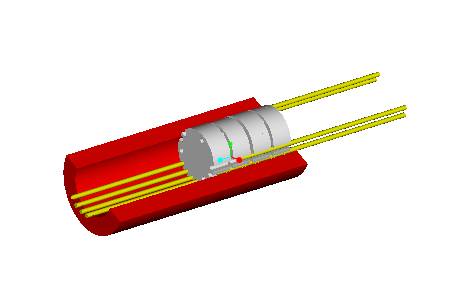

Heating Component

The subassembly rests in one end of a cylindrical ceramic heater and the

additional space in the heater is used to heat the incoming gas flows. The

incoming hydrogen and oxygen flows come in near the bottom surface of the heater

while the exhaust flows exit the heater near the sidewalls. The heating setup is

shown below.

Insulation and Housing

The heater and subassembly will be insulated using alumina bricks from

Cotronics, Inc. When the heater is at operating temperature, the insulation will

allow the system to be safely handled as the surface of the bricks will only

become warm to the touch. The whole system will rest inside of an outer housing

unit. The housing unit aides in the mobility and containment of our test

facility.