![]()

Products

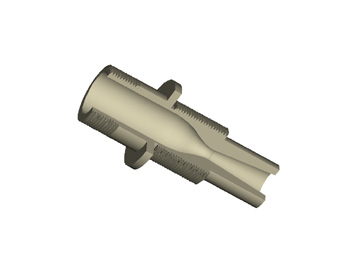

The single stage ejector consists of three basic sections: the nozzle, the suction port and chamber, and the diffuser. The ejector acts as a momentum transfer pump. A high-pressure motive gas, in this case compressed air, expands across a converging-diverging nozzle and accelerates to supersonic velocity. This high-velocity motive air entrains the air from the suction port and then compresses it across the converging-diverging diffuser by converting the velocity head to pressure head. Pushed against the discharge pressure (i.e. ambient air) of the air-jet ejector, this motive gas and suction gas mixture maintains a pressure differential between the suction port and the discharge pressure.

The converging diverging nozzle

The air-jet ejector will be made out of steel and insulated to keep the motive gas at a high temperature for optimal performance. The air-jet system will use less then 40% of the bleed-off available from the compressor, allowing other standard devices to run off of the same bleed off. The size of the air-jet ejector will vary between 40 and 60 centimeters with a height of 15 to 25 centimeters.

Technical specifications with respect to other engine designs are available upon request.

[

Home | Products | Company | Email ]